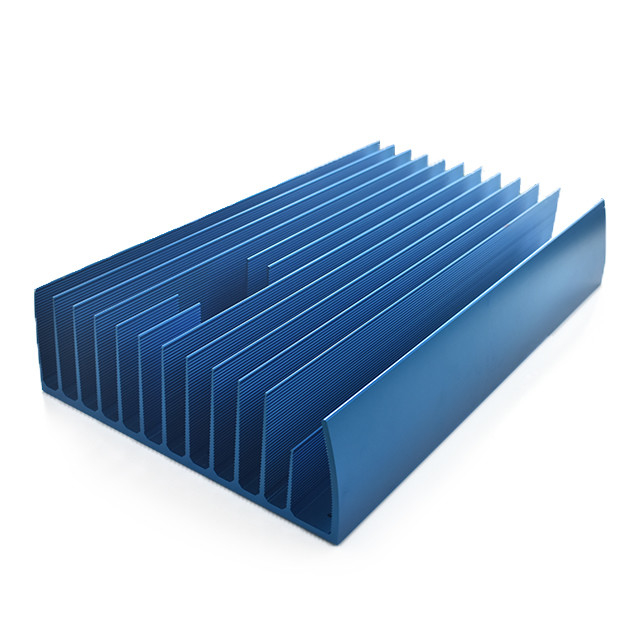

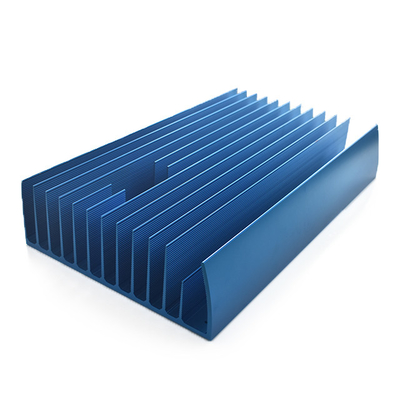

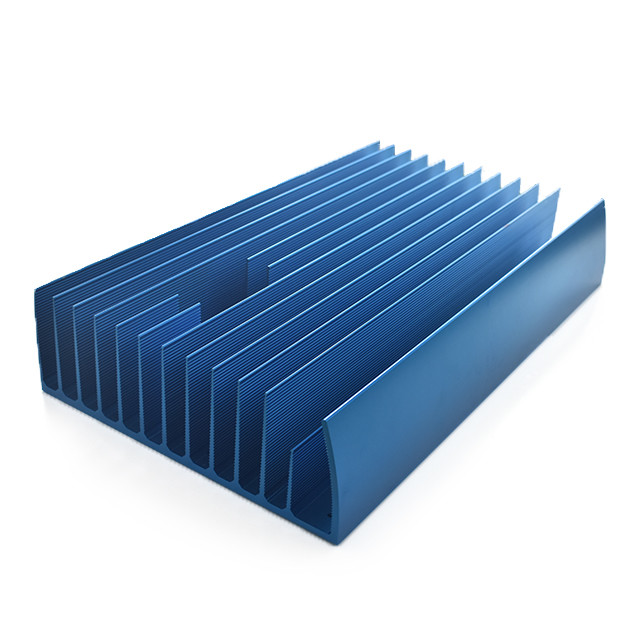

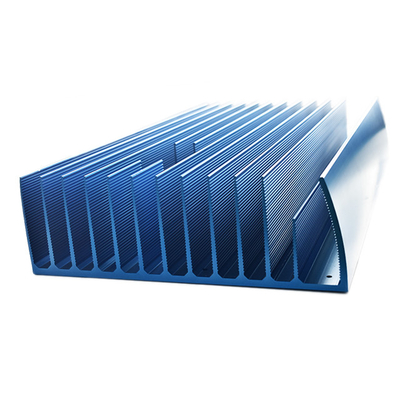

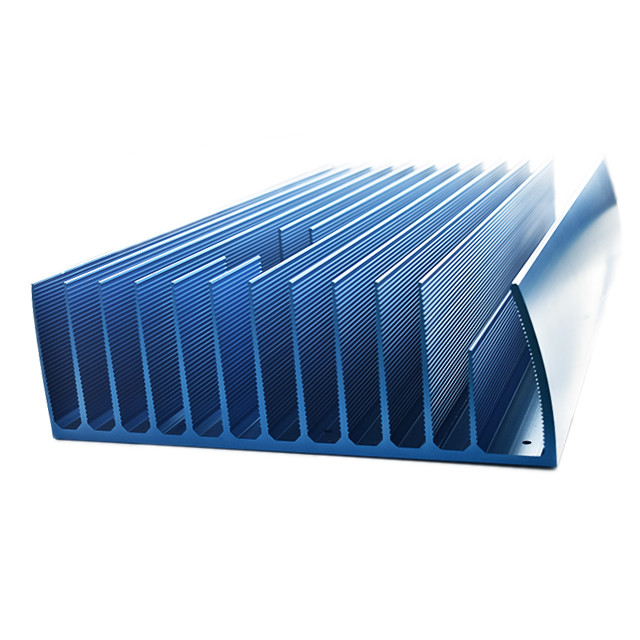

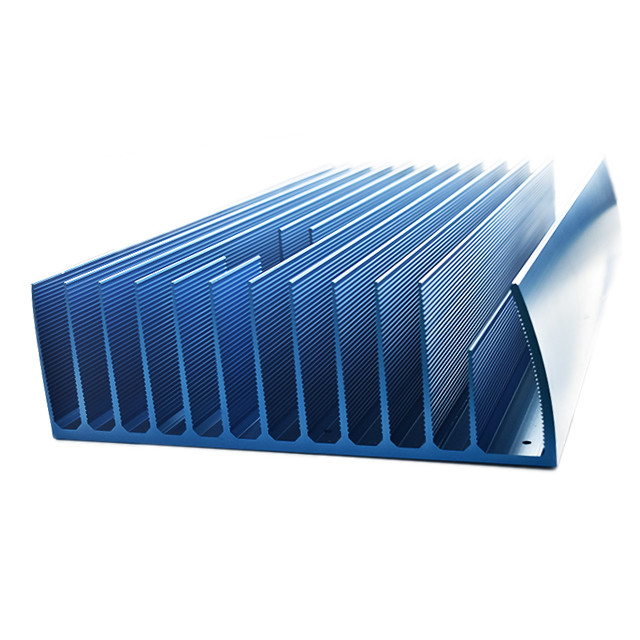

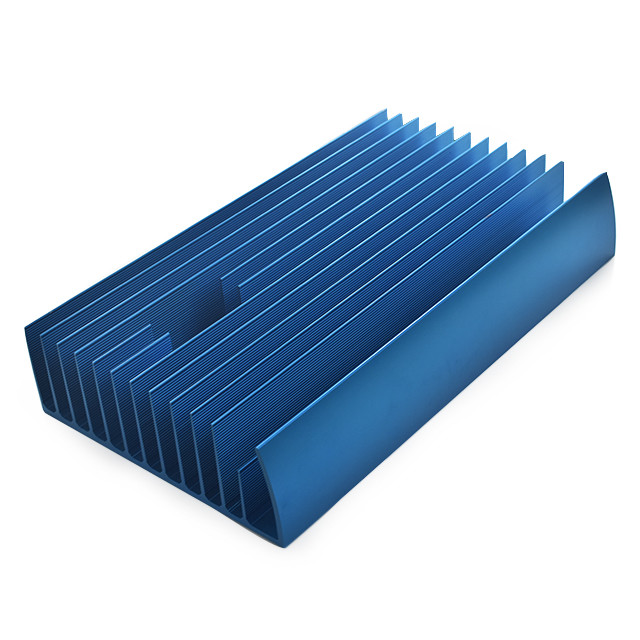

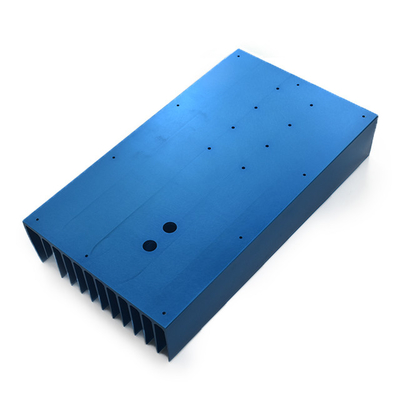

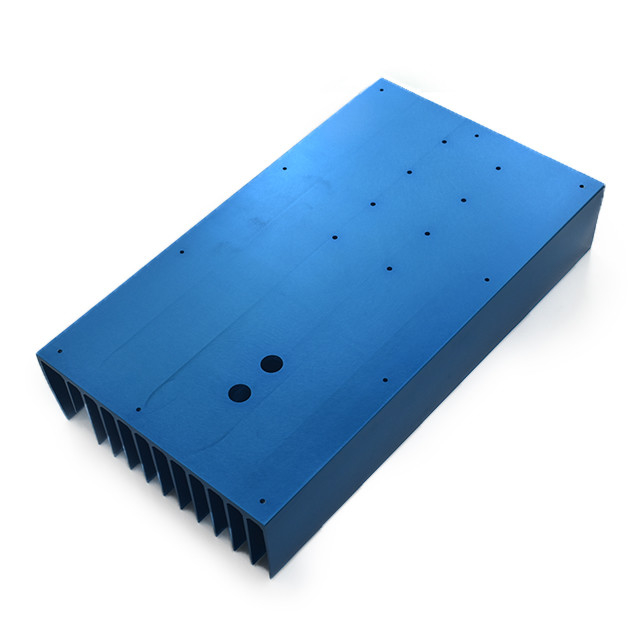

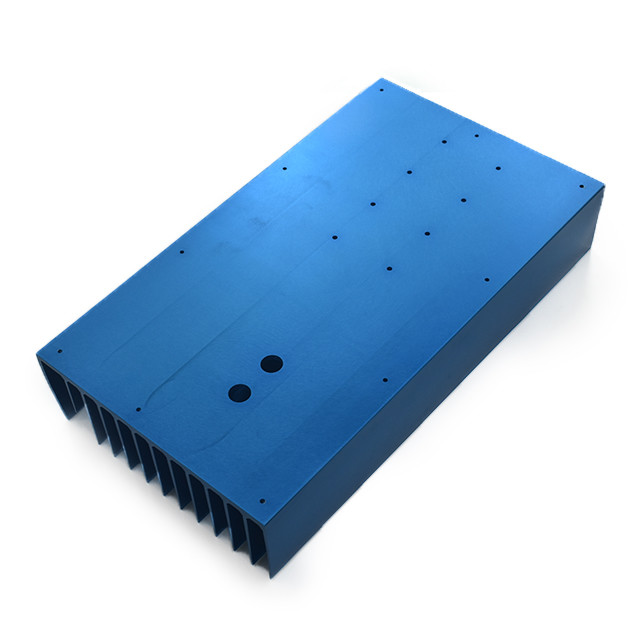

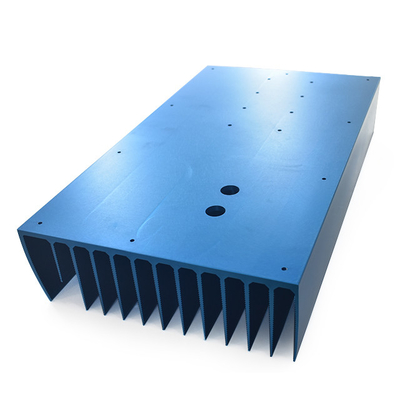

450mm Max Width Anodizing Blue Aluminum Extruded Heat Sink With ISO9001

Quick Detail

| Raw Material |

AL6063-T5 |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

Cutting/Wood machining/CNC/Riveting |

| Surface treatment |

Andizing blue |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Electronic equipment heat sink |

| MOQ Request |

100/500/1000 |

Description

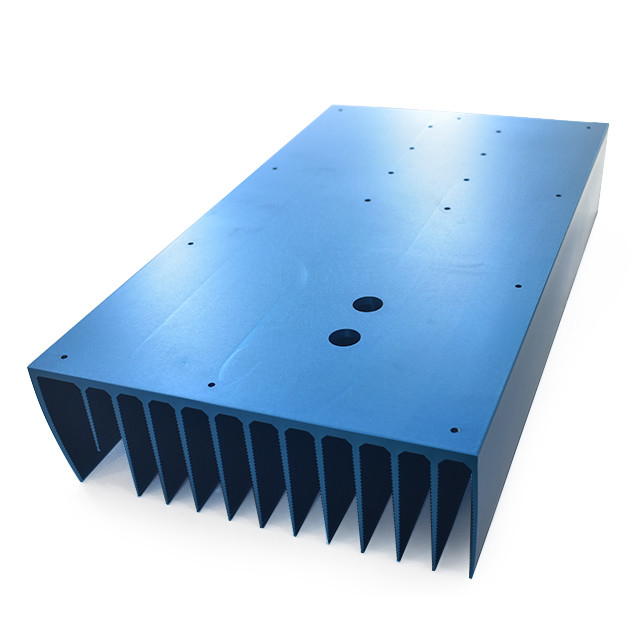

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing , the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

Note

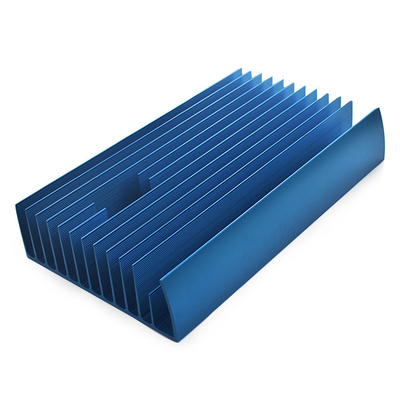

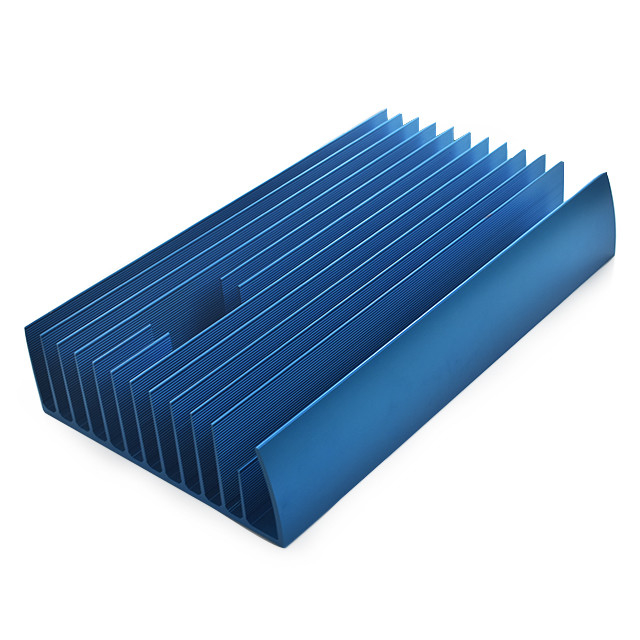

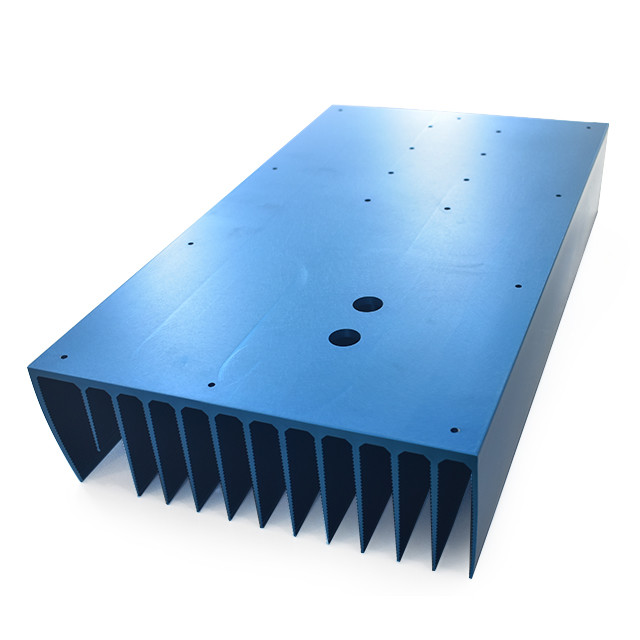

Aluminum profile radiators do have many advantages. For example, the aluminum profile radiators, heat pipe radiators, copper-aluminum composite liquid-cooled radiators, thyristor radiators, densely toothed radiators, etc. of Fodor radiators are all made of aluminum. The heat dissipation effect is good and it is very popular. The main advantages are as follows:

1. Super plasticity: The aluminum alloy profile is light in weight and high in strength. It can be extruded into a variety of shapes according to the customer's heat dissipation requirements.

2. Long service life: The aluminum radiator also has the characteristics of corrosion resistance, small deformation, strong fire resistance, and the service life can reach 50-100 years.

3. Excellent weather resistance: the aluminum alloy radiator profile has been treated by various processes, and the surface is resistant to acid and alkali corrosion and is not polluted by air, and can maintain its inherent color and luster for a long time.

Which type of aluminum profile is used for the radiator?

The radiator aluminum profile, as the name implies, is an aluminum profile used for heat dissipation. At present, there are copper radiators on the market, but due to the high cost of copper, and the processing performance is not as good as aluminum, the use of aluminum alloy instead of copper radiators is more suitable for market demand.

Aluminum extruded heat sink

At present, the most widely used model is 6063 material. This material has good heat dissipation effect, easy processing, and good surface treatment effect, so it is widely favored by extrusion manufacturers.

Why is extruded aluminum profile radiator better than die-cast aluminum profile radiator?

The denser the texture of the material, the better its thermal conductivity. After the extruded profile is extruded and stretched, the inter-molecular gap (lattice gap) has been compressed, and the density has been greatly increased. The die-casting profile has not been extruded, the molecules are relatively loose, and of course the density is not as good as that of the extruded profile, so its heat dissipation is not as good as that of the extruded profile. The strength of the extruded profile is also higher.

we can offer aluminum extruded heat sink, small qty will be acceptable.welcome inquiry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!