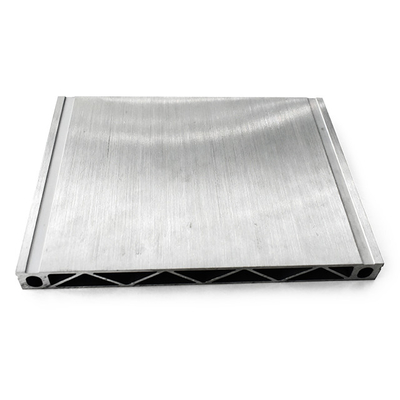

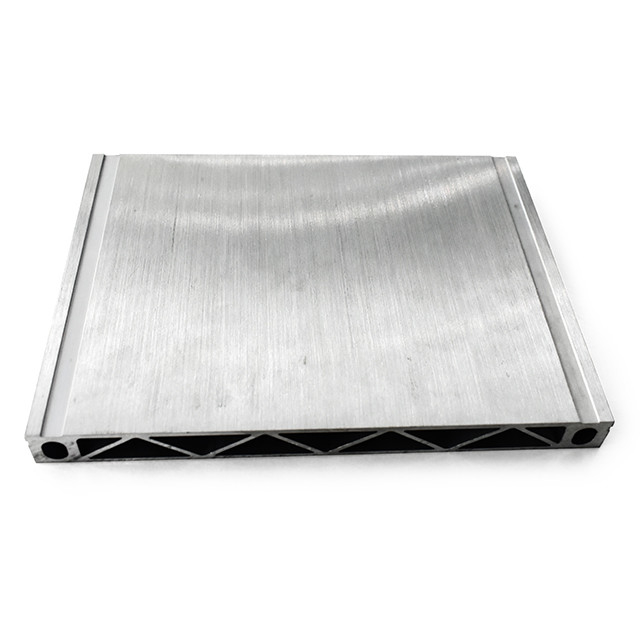

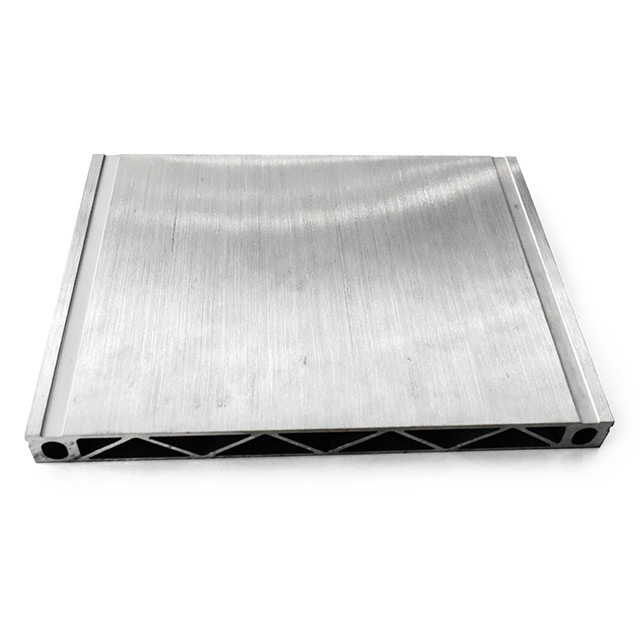

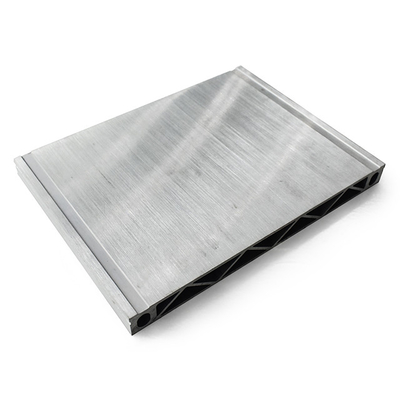

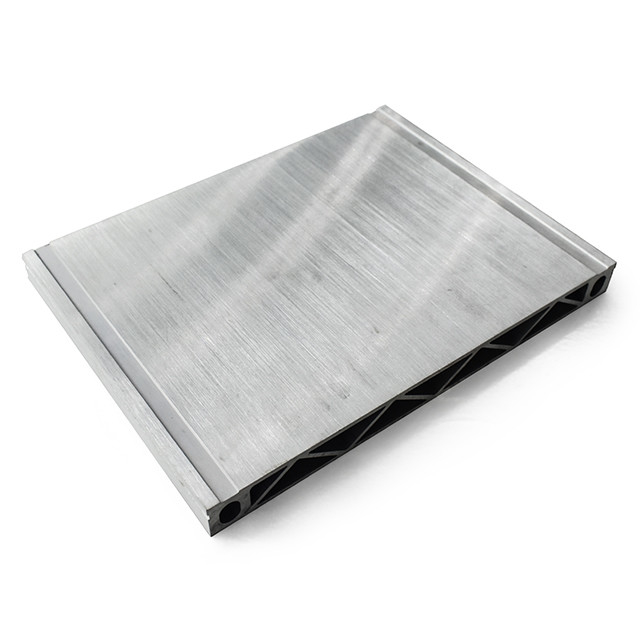

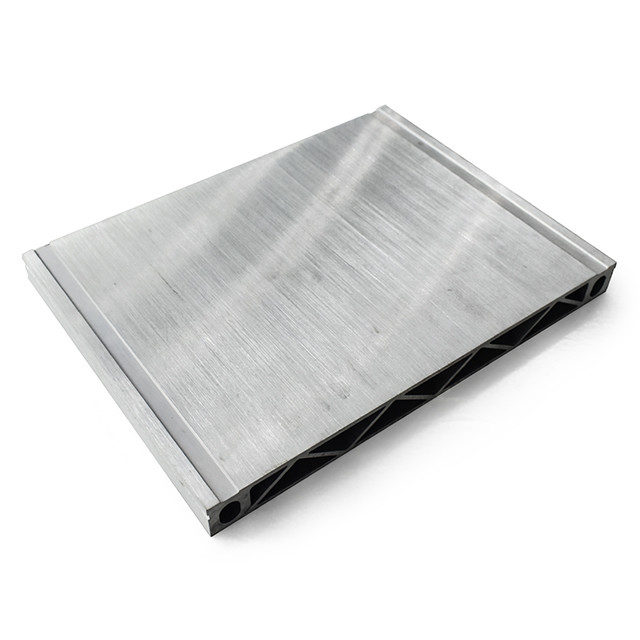

New Energy Battery Aluminum Extruded Heat Sink With Anodizing Nature Surface Treatment

Quick Detail

| Raw Material |

AL6063-T5 |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

Cutting/Wood machining/CNC/Riveting |

| Surface treatment |

Andizing nature |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Electronic equipment heat sink |

| MOQ Request |

100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing , the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

Note

Which type of aluminum profile is used for the radiator?

The radiator aluminum profile, as the name implies, is an aluminum profile used for heat dissipation. At present, there are copper radiators on the market, but due to the high cost of copper, and the processing performance is not as good as aluminum, the use of aluminum alloy instead of copper radiators is more suitable for market demand.

Aluminum extruded heat sink

At present, the most widely used model is 6063 material. This material has good heat dissipation effect, easy processing, and good surface treatment effect, so it is widely favored by extrusion manufacturers.

Why is extruded aluminum profile radiator better than die-cast aluminum profile radiator?

The denser the texture of the material, the better its thermal conductivity. After the extruded profile is extruded and stretched, the inter-molecular gap (lattice gap) has been compressed, and the density has been greatly increased. The die-casting profile has not been extruded, the molecules are relatively loose, and of course the density is not as good as that of the extruded profile, so its heat dissipation is not as good as that of the extruded profile. The strength of the extruded profile is also higher.

What is the difference between industrial-grade high-power aluminum radiator and general electronic components?

The most intuitive difference is the size. General electronic components or radiators for PC computers are very small. High-power aluminum radiators, as well as water-cooling plates, heat pipe radiators, etc. (the main materials are aluminum), are generally used in large equipment, such as SVG, APF, inverters, frequency converters, energy storage equipment, photovoltaics Equipment, welding machines, laser power supplies, etc., many manufacturers are doing this, such as Xihe radiator factory. For more differences, you can directly consult the manufacturer. In addition, many radiators for high-power devices need to be contacted by the manufacturer. customized.

we can offer aluminum extruded heat sink, small qty will be acceptable.welcome inquiry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!