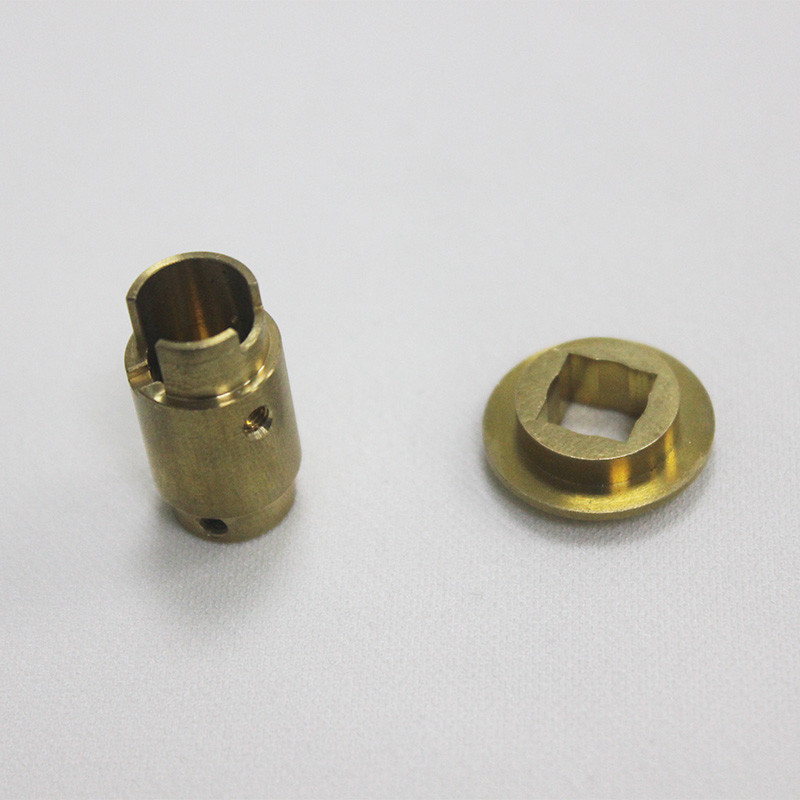

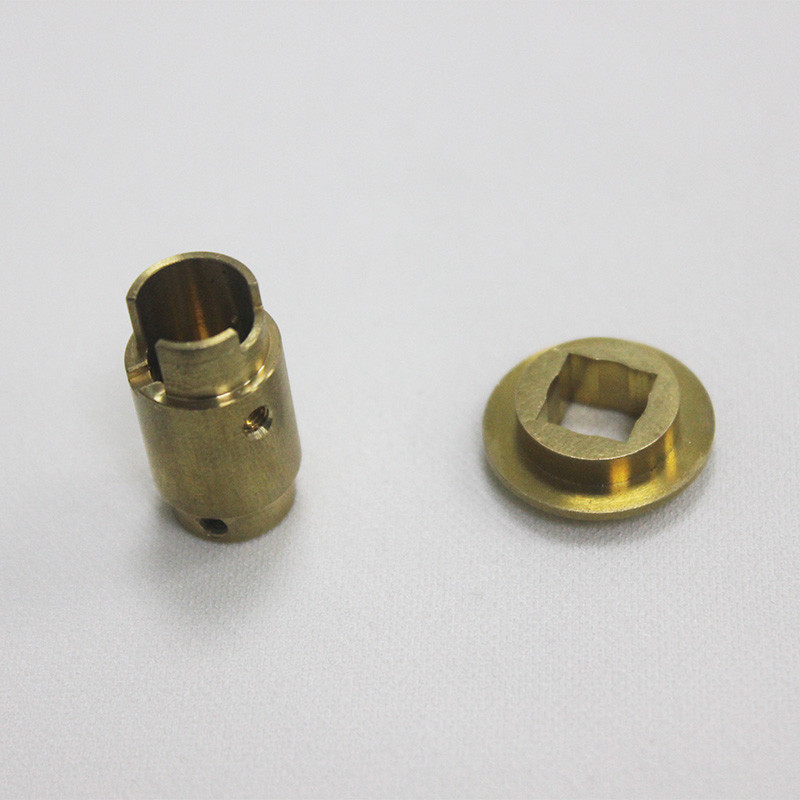

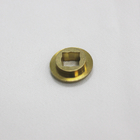

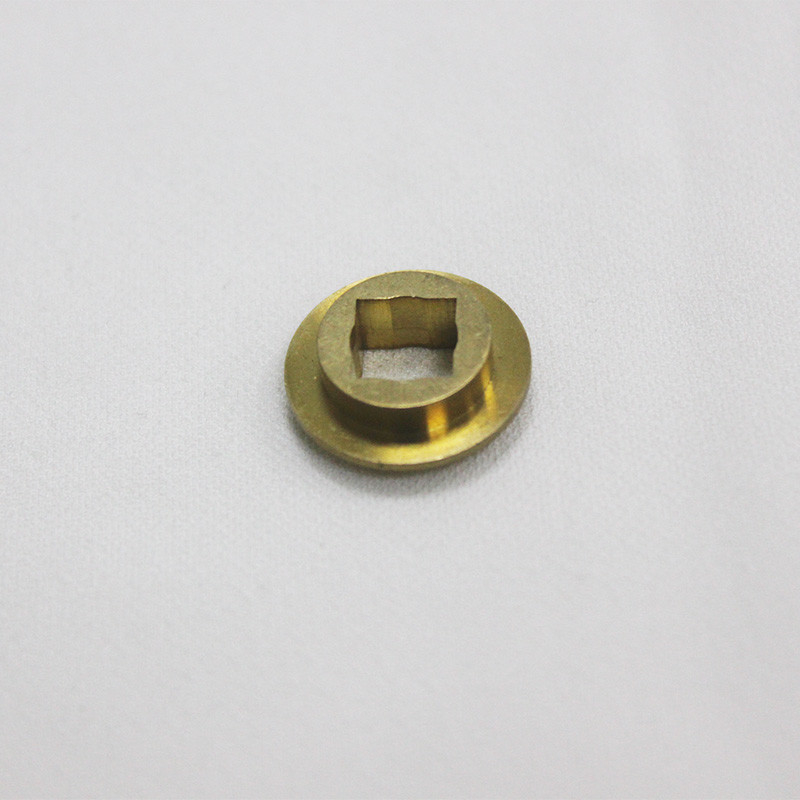

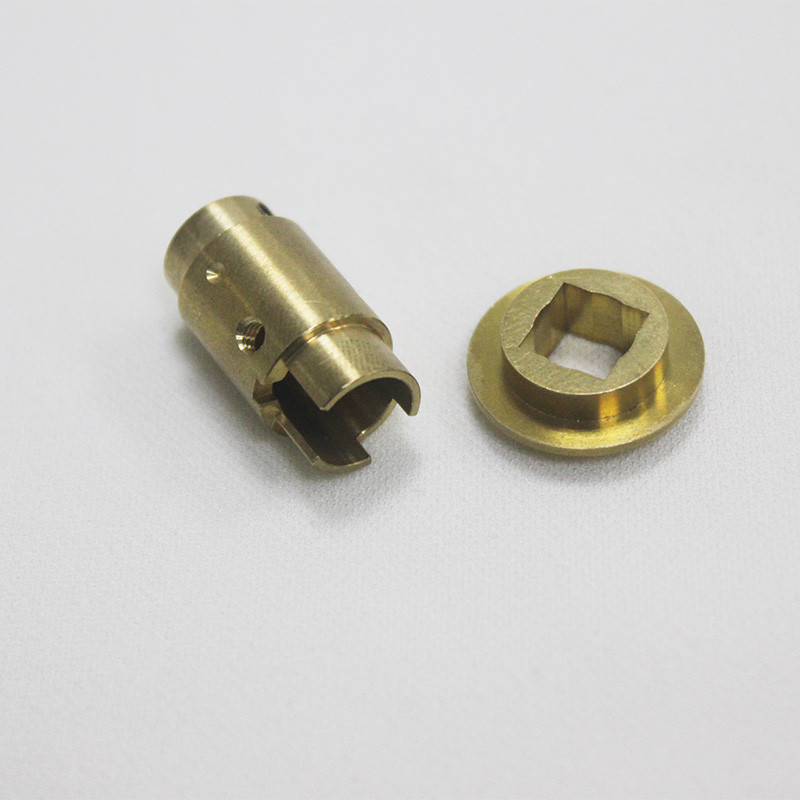

Copper Precision Drilling And Milling CNC Machining Parts For Nut

Quick Detail

| Raw Material |

Copper |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

Cutting/Wood machining/CNC/Riveting |

| Surface treatment |

clean |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Nut |

| MOQ Request |

100/500/1000 |

Description

This CNC Machining Part is based aluminum profile 6061 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, use the CNC Gear shovel machine to do the dimension, the third is that accroding to the drawing, uthe forth is that use the CNC to do exact dimension, the fifth is do anodizing , the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

Note

What should we pay attention to when machining CNC precision parts?

1. The CNC lathe processor must read the content of the process card clearly before processing, clearly know the part, shape, drawing and size of the workpiece to be processed, and know the processing content of the next process.

2. Before the workpiece is clamped, the size of the blank should be measured whether it meets the requirements of the drawing. When the workpiece is clamped, it must be carefully checked whether its placement is consistent with the programming operation guide.

3. Finish machining only after rough machining self-inspection. After finishing processing, workers should conduct self-inspection on the shape and size of the processed parts: check the basic length and width dimensions of the processed parts on the vertical surface; measure the basic point size marked on the drawing for the processed parts of the inclined surface.

4. After the worker completes the self-inspection of the workpiece and confirms that it is in compliance with the drawings and process requirements, the workpiece can be removed and sent to the inspector for special inspection.

What are the benefits of CNC precision parts processing?

1. Multi-axis control and multi-axis linkage: The commonly used machining centers are mostly three-axis linkage. By increasing the swing angle and increasing the rotation coordinates, it can form four-axis linkage, five-axis linkage, seven-axis linkage, and even more-axis linkage processing. center.

2. Parallel machine tools: The functions of commonly used machining centers are relatively fixed. Vertical machining centers, horizontal machining centers, or machining centers, turning centers, etc. are combined to form a machining system, which increases the machining range and processing capacity of the machine tool.

3. Tool breakage alarm: use infrared, acoustic emission, laser and other detection methods to detect the tool. If tools are found to be worn or damaged, promptly alarm, automatically compensate or replace spare tools to ensure product quality.

4. Tool life management: unified management of multiple blades on a tool, or several tools working at the same time, to improve processing efficiency.

5. Automatic protection of machine tool overload: The machine tool can automatically protect the machine tool according to the load during processing. When the load exceeds the maximum load set by the machine tool, the machine tool will automatically shut down. The load size can be set and changed by yourself.

6. Machining dynamic entity simulation: During the machining process, the machining state of certain parts of the machine tool is not easy to observe. If the dynamic entity simulation function is added, the machining state of the workpiece can be observed at any time, which can prevent undesirable phenomena in machining, such as Knife, over-cutting, not only, unreasonable steps, etc.

7. On-line inspection of workpieces: also called real-time inspection, which means real-time inspection of workpieces in the process of processing to find and correct errors in time. This function can effectively avoid the problem of re-clamping and positioning caused by unqualified inspection after conventional processing, shortening production time and improving production efficiency.

8. Adaptive control: The machine tool with this function can detect the changes in the cutting conditions (such as cutting force, temperature, etc.) that it senses during the machining process, and control the machine tool to change the cutting amount in time through the adaptive control system, so that the machine tool and the tool are always Maintain the best condition, so as to obtain higher cutting efficiency and processing quality, and extend the service life of the tool.

We can offer CNC machining partd for custom design.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!