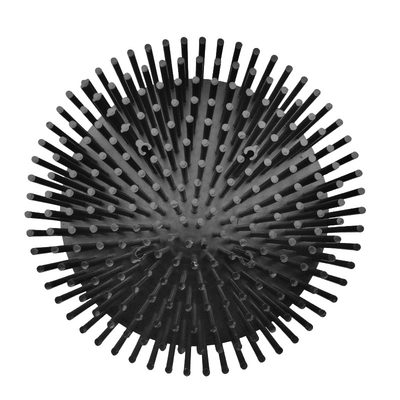

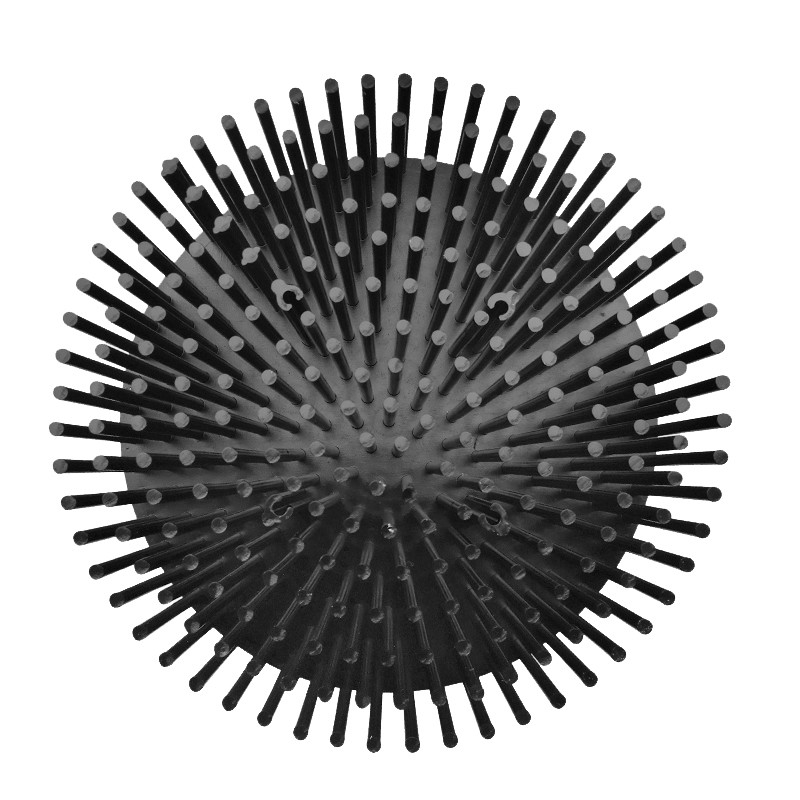

Existing Mold Aluminum Cold Forging Led Grow Heat Sink With Diameter 133mm 50W LED Lighting

Quick Detail

| Raw Material |

AL1070/1060 |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

Forged/cutting/laser/CNC/Anodizing |

| Surface treatment |

Andizing Black |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

LED heat sink 50W |

| MOQ Request |

100/500/1000 |

Description

Cold forging is an impact forming process that plastically deforms a piece of raw material, under high compressive force, between a punch and a die within suitable equipment such as a machine press.

Some basic techniques include extrusion (forward, backward, forward and backward), coining, upsetting, and swaging. These techniques may take place in the same punch stroke or in separate operations, depending on the specific application requirements.

In essence, cold forging is a displacement process that forms existing material into the desired shape; contrast this with conventional machining, in which material is removed to create the desired shape. As seen in the following sections, this distinction offers several significant advantages. The final section provides some of the key factors that should be kept in mind when considering cold forging as a manufacturing process.

There are generally 2 types of dies used in cold forging:

Open Forging: Material is allowed to escape after the cavity is filled.

Advantage: Lower stress and load

Disadvantage: Some post-machining may be required, depending on application requirements

Closed Forging: Die cavity volume is exactly the same as material volume in order to achieve outputs of net shape or near net shape.

Advantage: Eliminates need for post-machining

Disadvantage: Higher stress and load; die could be seriously damaged if the material is in excess

What are the advantages of cold forging?

The major advantages of cold forging are close dimensional tolerances, good surface finish quality, and the use of lower cost materials to obtain the required strength by work hardening without requiring heat treatment

Note:

The craft is below:

1: cold forging processing

2:Cut the pin

3: lathe

4:CNC

5:Anodizing.

Fodor Technology can offer the desing of cold forging heat sink , thermal Simulation Analysis and production service.If you have any cold forigng heat sink inquiry, please send request to Fodor, the mail box is fodor@fodorheatsink.com.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!