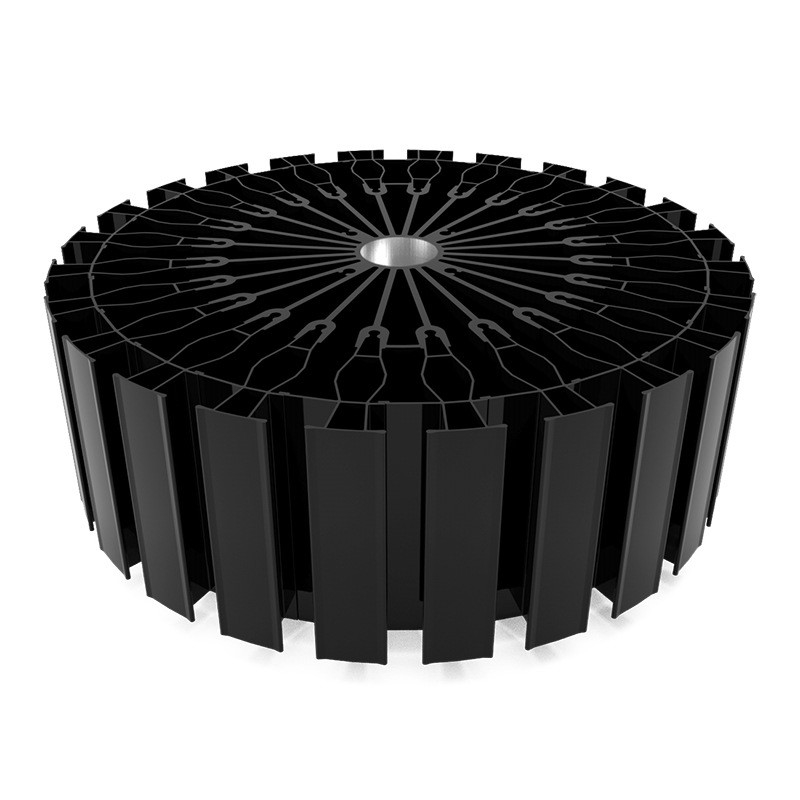

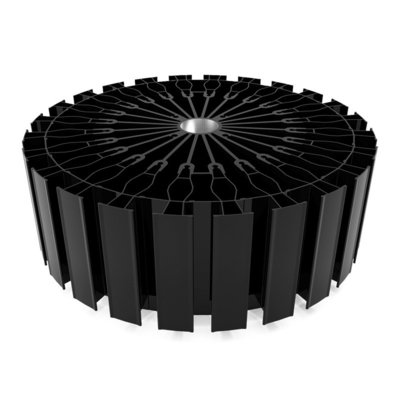

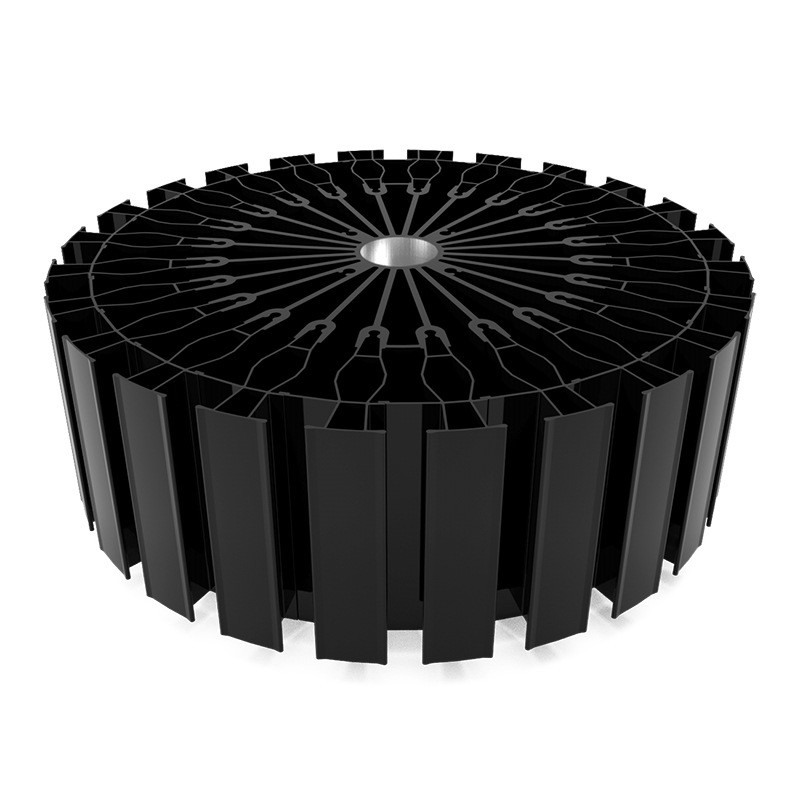

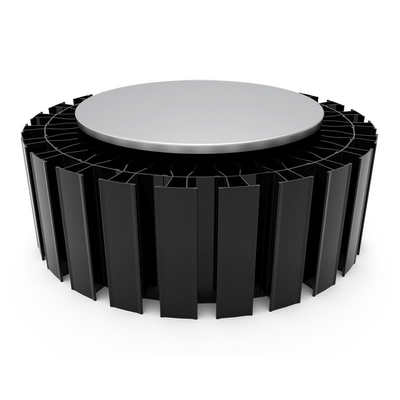

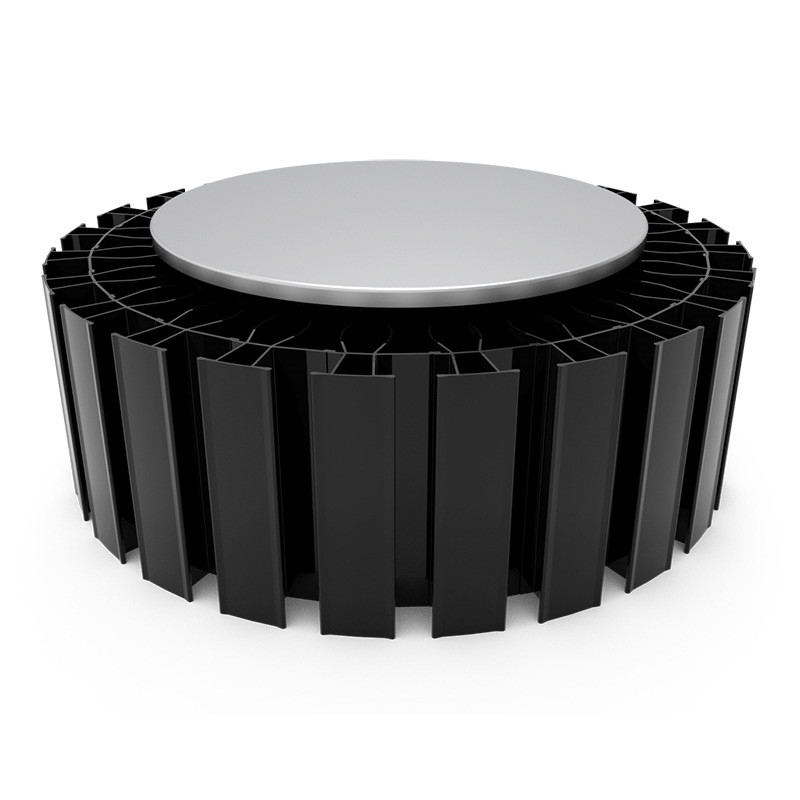

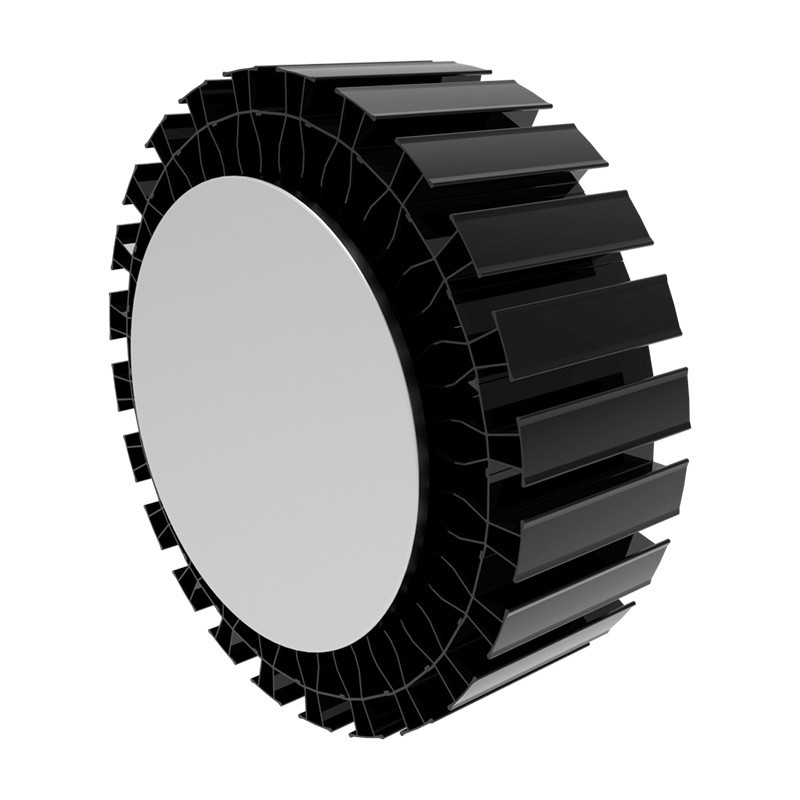

150W Aluminum Extrusion Heat Sink With Anodizing Black For Led Lighting

SGS-AL6063-T5.PDF

Quick Detail

| Raw Material |

AL6063-T5/6061 |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

Cutting/Wood machining/CNC/Anodizing |

| Surface treatment |

black or custom |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

heat sink |

| MOQ Request |

100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

Notes

What happens if your LED lights overheat?

In extreme cases overheating LEDs can result in physical damage to the LEDs themselves, plastic lenses, wires, connectors, printed circuit boards, drive electronics etc.

What are the two types of heat sink?

A heat sink thus transfers the heat from the high temperature component such as a transistor to the low-temperature medium such as air, oil, water or any other suitable medium through conduction and then convection. There are two types of heat sinks, namely the passive heat sink and the active heat sink

What is the difference between a heat spreader and a heat sink?

Heat sinks with built in cooling fans are a simple, lightweight, and completely self-contained cooling solution. Depending on the available airflow they can often out-perform a similar sized heat-spreader. Heat spreaders have a large, flat surface on top. They have no fan and no fins

How do I choose a heatsink?

In general, the following are the major Heat Sink Design Consideration factors for good selection and design of Heat Sinks.

Device Operating Temperature Range (Ambient Temperature)

System IP Rating.

Product Size.

System Cost.

Availability of Convection mode cooling options.

Insulation/Isolation Requirements.

How do I optimize my heat sink?

A heat sink design can be improved by adding fans or pins, choosing an alternative material, or adding in forced cooling via convection. A heat sink works by absorbing thermal energy in the surrounding environment from electrical component inefficiency via the conduction method of heat transfer.

How do I increase my heatsink?

Natural and Forced Convection – Since a heat sink works by dispersing heat to the surrounding air, the process can be improved by moving that free air into forced convection air parallel to the heat sink fins by the use of a heatsink fan. Using forced air convection significantly increases the rate of heat transfer.

If you need solve solution of heat sink, you can send inquiry to us, we will check and desing the heat sink for your request.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!