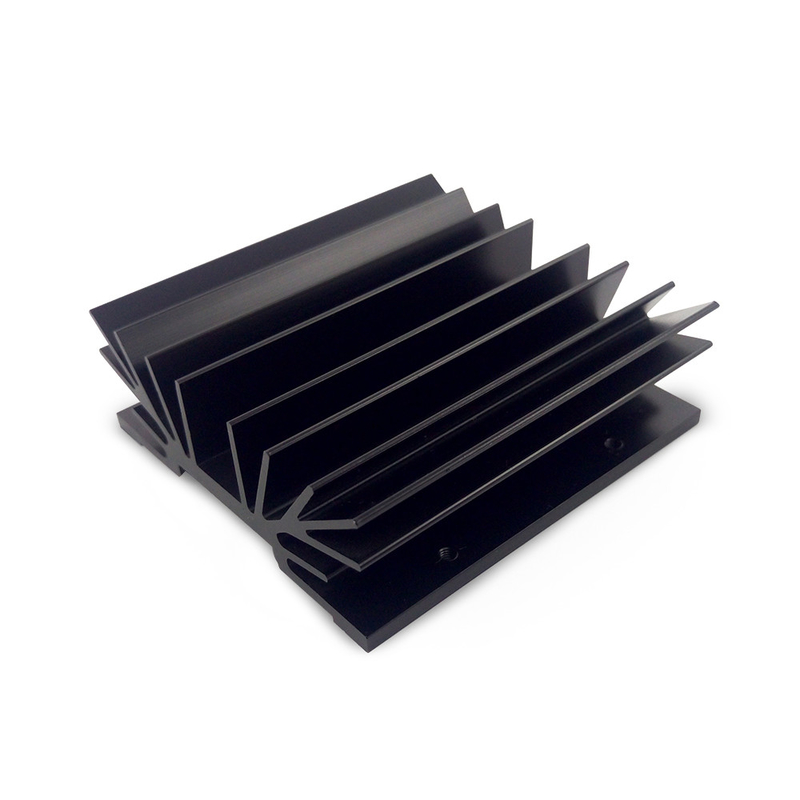

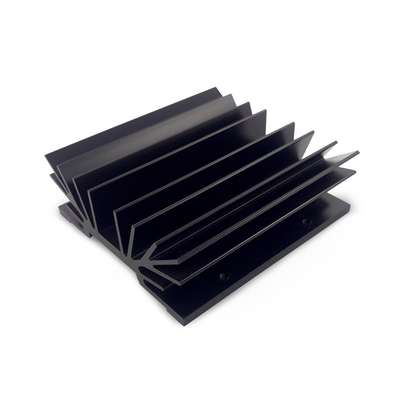

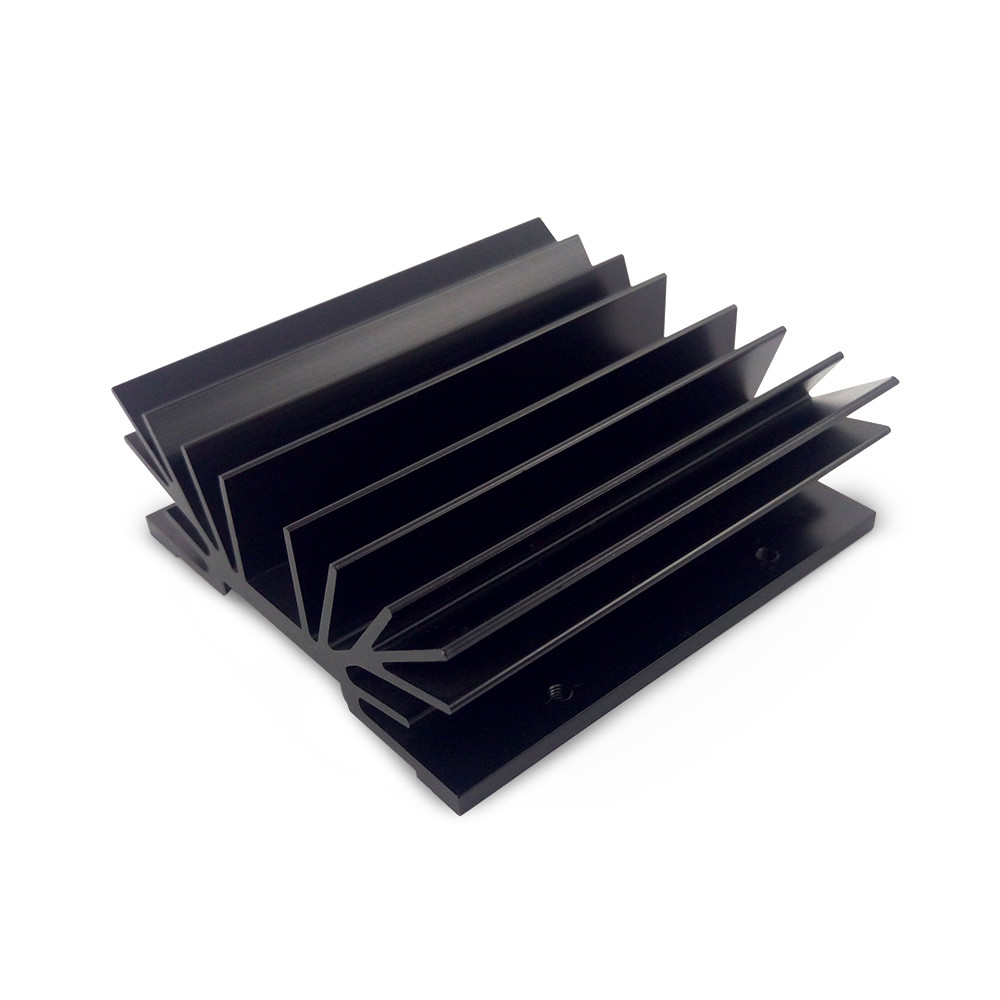

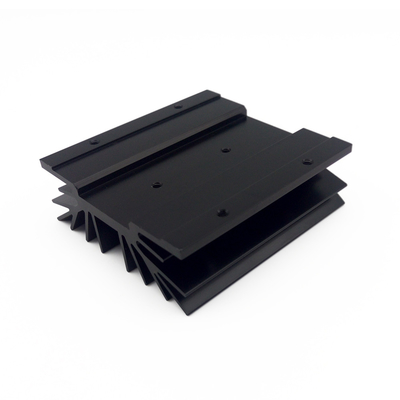

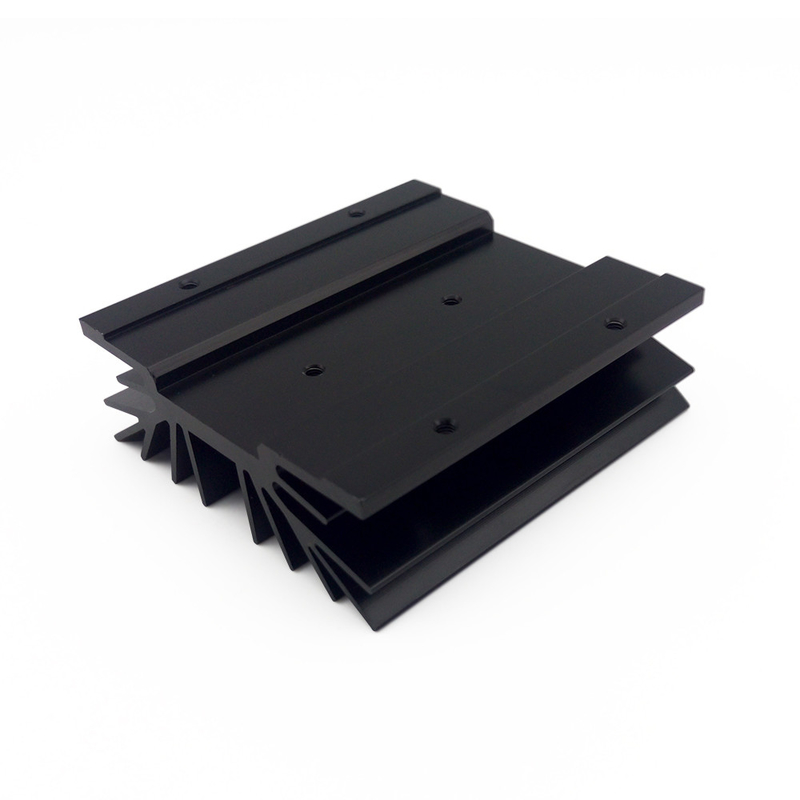

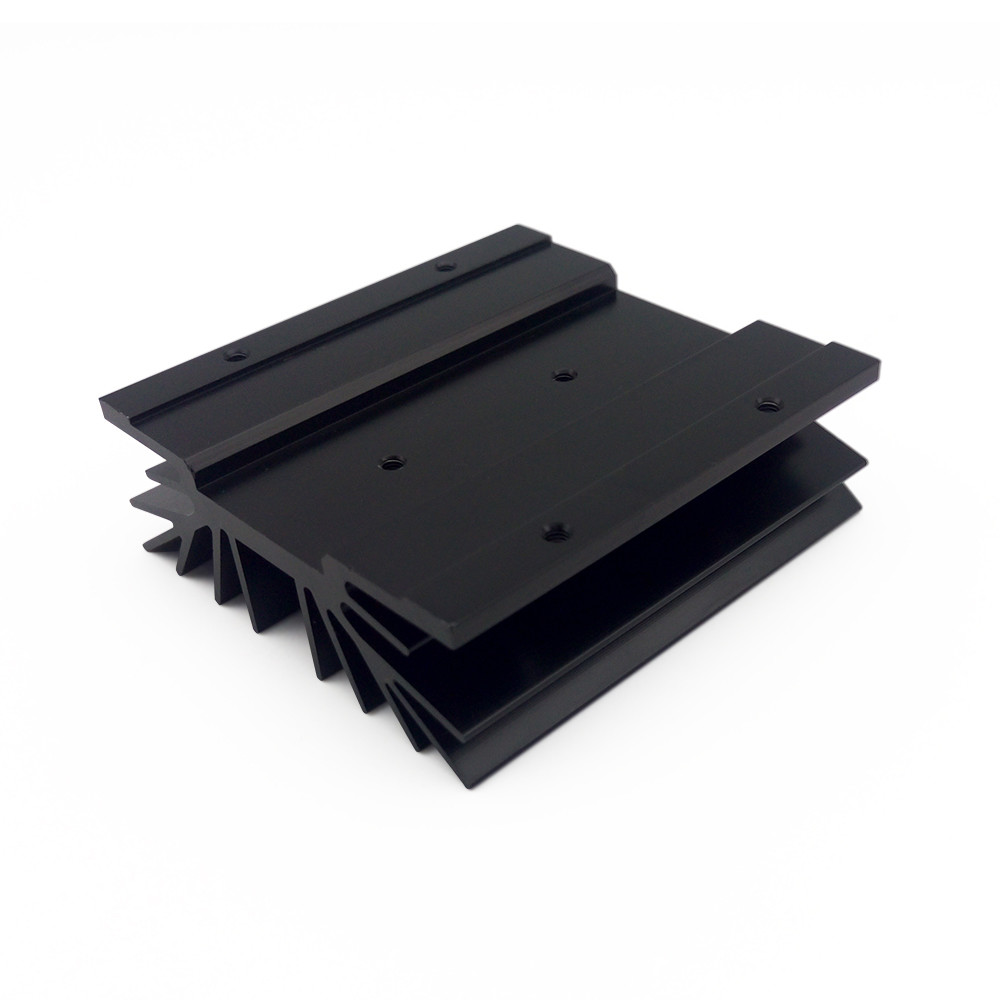

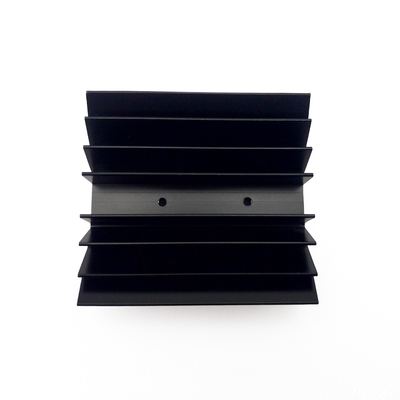

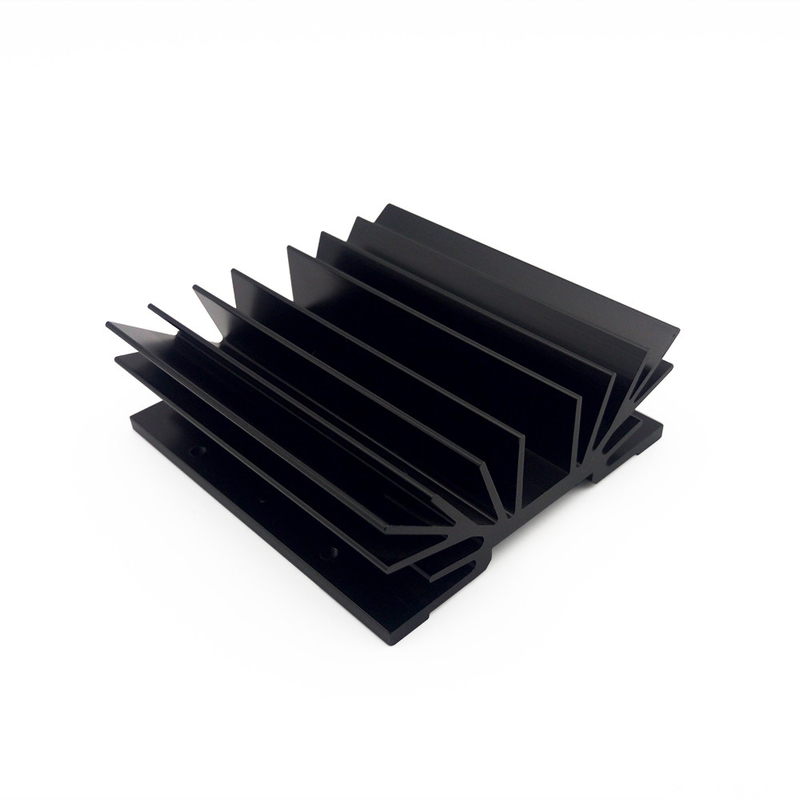

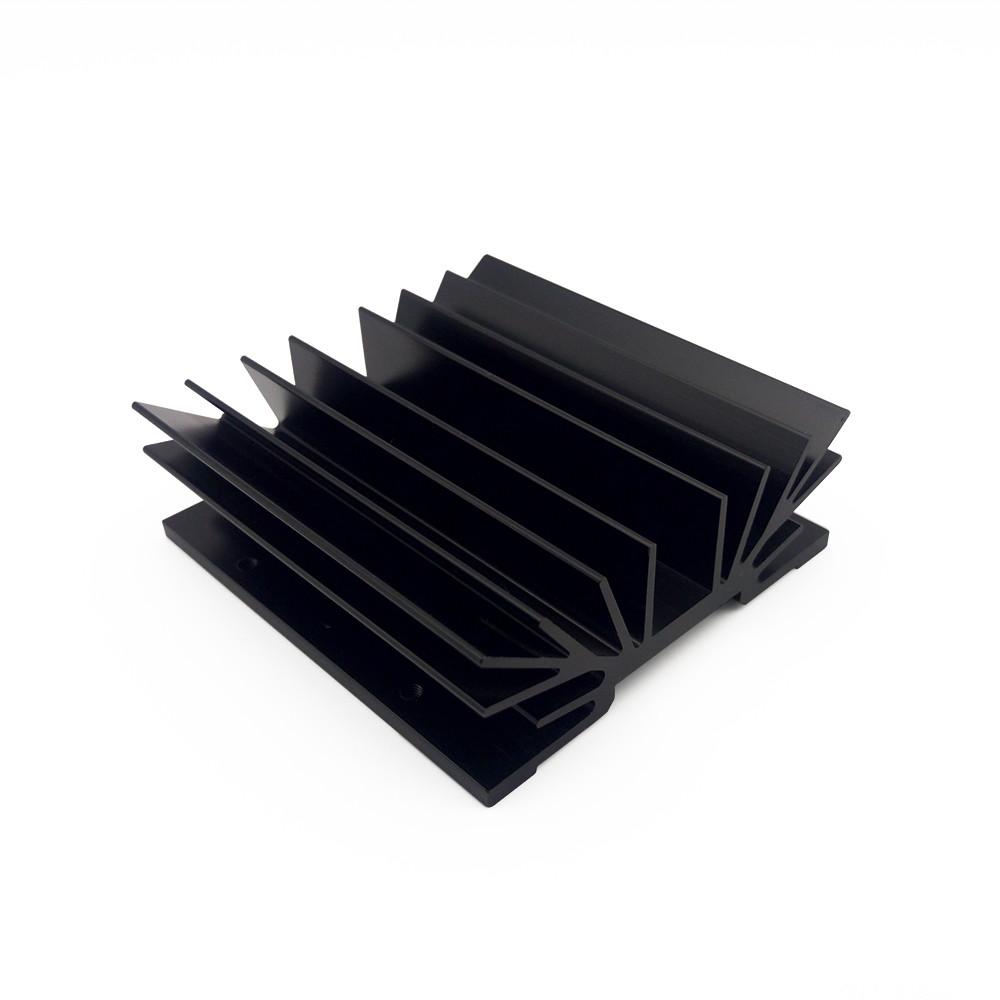

Heat Sink Standard Extrusion Profiles With Anodizing Black Surface Treatment

Quick Detail

| Raw Material |

AL6063-T5 |

| Custom Service |

Yes, OEM/ODM Service |

| Free design service |

We can offer the free design heat simk service. |

| Processing Technology |

Cutting/Wood machining/CNC/Riveting |

| Surface treatment |

Anodizing Black |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

LED heat sink |

| The other styles heat sink |

We can offer cold forging heat sink, skived heat sink, die casting heat sink, heat pipe heat sink, cold plate

|

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

RFQ

What is the most effective heat sink?

Copper is one of the best materials to choose for heat sinks as it has a high thermal conductivity. But aluminum is most commonly used due to it's lower cost and relatively high thermal conductivity.

Metals with excellent thermal conductivity such as diamond, copper and aluminum make the most efficient heat sinks. However aluminum is more commonly used due to its lower costs.

Other factors that affect a heat sink’s performance include:

- Thermal Resistance

- Airflow

- Volumetric resistance

- Fin density

- Fin spacing

- Width

- Length

Heat sinks are used to cool various electronics components whose heat dissipation abilities are is insufficient to dissipate all the excess heat. These devices include:

- Power transistors, thyristors and other switching devices

- Diodes

- Integrated circuits

- CPU Processors

- Graphic processors

- LEDs

The heat sinks can further be classified by their physical designs and shapes, material used and more. Typical heat sinks are:

- Stamped

- Machining

- Bonded-fin

- Folded-fin

- Forged Heat Sinks

- Single Fin Assembly Heat Sinks

- Swaged Heat Sinks

- Skived Heat Sinks

Notes

This is sunflower aluminum profile heat sink.

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, thereby allowing regulation of the device's temperature. In computers, heat sinks are used to cool CPUs, GPUs, and some chipsets and RAM modules. Heat sinks are used with high-power semiconductor devices such as power transistors and optoelectronics such as lasers and light-emitting diodes (LEDs), where the heat dissipation ability of the component itself is insufficient to moderate its temperature.

We offer the Aluminum Profile Heat sink service for custom and exsiting mold.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!