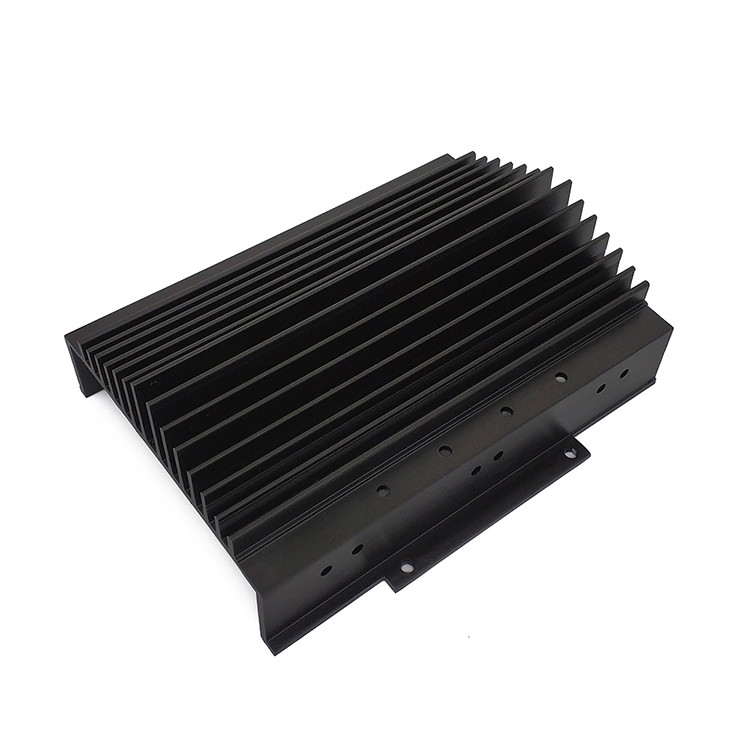

Heat Sink Aluminum Extrusion Profiles With Surface Treatment Anodizing Black

Quick Detail

| Raw Material |

AL6063-T5 |

| Custom Service |

Yes, OEM/ODM Service |

| Free design service |

We can offer the free design heat simk service. |

| Processing Technology |

Cutting/Wood machining/CNC/Riveting |

| Surface treatment |

Anodizing Black |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Electronics heat sink |

| The other styles heat sink |

We can offer cold forging heat sink, skived heat sink, die casting heat sink, heat pipe heat sink, cold plate

|

Description

This aluminum profile housing heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

CATEGORY: HEATSINK ENCLOSURES・HEATSINK CASES・COOLING CASE・HEAT DISSIPATING ENCLOSURE・FANLESS ENCLOSURE

RFQ

Heatsinks for Electronics Equipment

an overview or tutorial giving the basic facts about heatsinks or heat sinks, what they are and the thermal calculations required to choose the correct type.

Heatsinks are used in many pieces of electronics equipment to ensure that heat can be removed from pieces of equipment or particular components within them. For example with microprocessors running very hot these days, they normally have heatsinks clamped or attached to them, and in addition to this fans are also included in PCs to ensure that the components stay cool and operate within their operating temperature ranges. It is not only PCs that contain heat sinks. Many other pieces of equipment contain them. In fact heatsinks are used wherever there are sources of heat, and this heat needs to be removed.

Heatsinks can take a variety of forms, and they are widely available for electronics applications. If only a small amount of heat needs to be removed, small or simple heatsinks can be used. However if significant amounts of heat need to be removed, then more complicated heat sinks are needed. Using some relatively simple thermal calculations, it is possible to determine which heatsinks may be applicable for a given application. They are specified in a way that makes it possible to determine their performance.

Anodized Aluminum Heatsinks: What You Need to Know

Heat sinks play an important role in electronic and mechanical devices. They act as passive heat exchangers, transferring heat from hot components to a fluid medium (usually air).

There are different types of heat sinks. Some are made from copper and some are made from aluminum. But, most commonly, heatsinks are made through the process of aluminum extrusion. And those extruded heat sinks are also commonly anodized.

Why is this the case? What benefits does anodization offer? Let’s first talk about how anodization works and then the benefits it offers.

Metals with excellent thermal conductivity such as diamond, copper and aluminum make the most efficient heat sinks. However aluminum is more commonly used due to its lower costs.

Other factors that affect a heat sink’s performance include:

- Thermal Resistance

- Airflow

- Volumetric resistance

- Fin density

- Fin spacing

- Width

- Length

Heat sinks are used to cool various electronics components whose heat dissipation abilities are is insufficient to dissipate all the excess heat. These devices include:

- Power transistors, thyristors and other switching devices

- Diodes

- Integrated circuits

- CPU Processors

- Graphic processors

- LEDs

Notes

Aluminium enclosures with heat dissipation fins.

Suitable for audio amplifier chassis, fanless PCs, embedded computer enclosures, power supply boxes,LED ligting

We offer the Aluminum Profile Heat sink service for custom and exsiting mold.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!