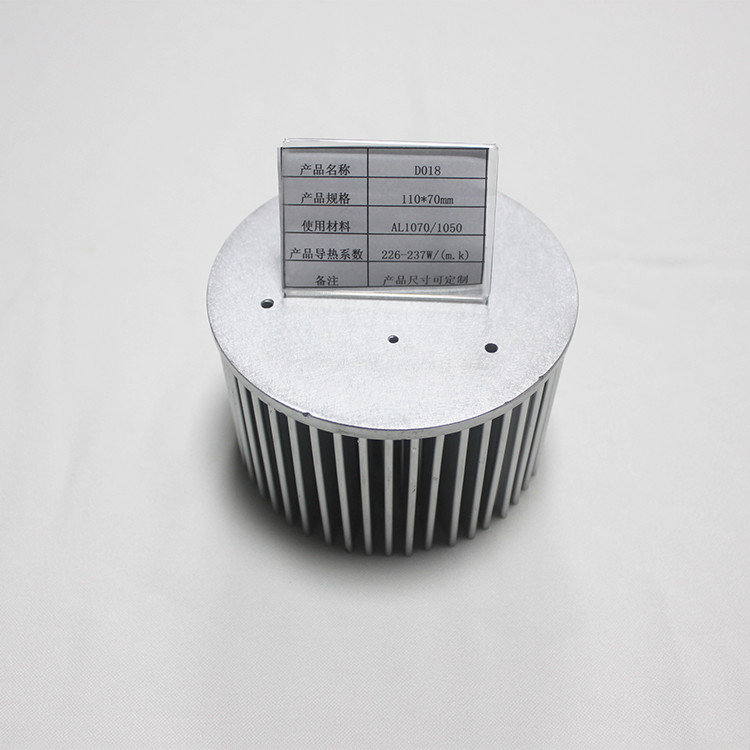

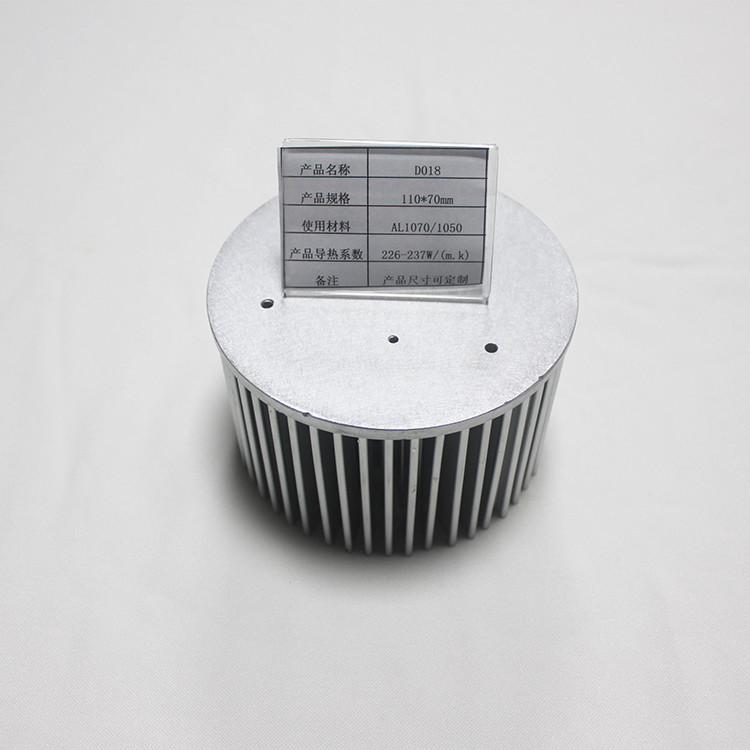

Cold Forging Round Natural Anodizing Heat Sink With Existing Mold Dia 110mm

Cold forging heat sink, Cold forged heat sink, LED cold forging heat sink,LED heat sink,COB LED lighting heat sink

Specification of Cold Forged Haet Sink

| Raw Material |

AL1070/1060/copper |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

Forged/cutting/laser/CNC/Anodizing |

| Surface treatment |

Anodizing black or Anodizing free style color |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Electronic equipment heat sink |

| MOQ Request |

100/500/1000 |

Description

Cold forged heat sinks are ideal for casting complex shapes with excellent thermal conductivity. The cold forging process can achieve almost perfect straightness, with more heat sinks per square millimeter. The shape of cold forging pin fin heat sink includes plate-fin heat sink, round pin heat sink and oval fin heat sink. The manufacture of forged heat sinks is very suitable for the use of copper, because copper heat sinks can be formed without high temperature and can cause minimal damage. The manufacture of cold forged heat sinks can usually include secondary machining operations, such as holes, chamfering, and steps to reduce unnecessary waste.

Fodor's market-leading pin fin design offers significant advantages for cooling LED applications including:

[LED Holder]

- The pins provide a high degree of surface area

- The cold forging process produces single piece of metal, high-density heat sink that provides outstanding thermal conductivity

- The pin fin design will work effectively in many orientations

- The forging technology provides the capability to incorporate custom features into the tool

- The precision machined 10mm thick base offers high thermal conductivity and provides a flat, uninterrupted surface for hole patterns to support LED attachment, optics, and mounting brackets

- Passive and Active (with integral fan) options

- All COB LED heatsinks will be shipped pre-drilled

Fodor LED heatsinks can be modified or customized to your application's needs:

1.About the cold forging heat sink

A Forged heatsink is manufactured using a modification of this process called cold forging. Cold forging uses high pressure and low temperature to ensure that no air bubbles, or other impurities are trapped in the material. This improves the thermal properties of the heatsink, and increases the density of the material.

A Forged heatsink is manufactured using a modification of this process called cold forging. Cold forging uses high pressure and low temperature to ensure that no air bubbles, or other impurities are trapped in the material. This improves the thermal properties of the heatsink, and increases the density of the material. Radian Thermal Products utilizes special open die tooling and intense pressure to produces high precision heatsinks with high aspect ratios. A Forged heatsink is typically manufactured one part at a time, and can be can be made from AL 6063 or C1100. Aspect ratio up to 35:1 are feasible, and no draft angles required on fins. Fins can be round, elliptical, straight or any combination on the same part.

The cold forging process is to forge the product at room temperature. The product has high shape and dimensional accuracy, good internal density, high strength of the workpiece, smooth surface, few processing procedures, and is convenient for mass production.

Cold forged heat sinks are widely used for heat dissipation of LED lamps. The shapes of cold forged heat sink include plate pin fin heat sinks, round pin heatsinks and oval fin heat sinks. Using cold forging heatsink will reduce the overall weight and volume of LED lamps to achieve The purpose of reducing the overall cost is to make the product more competitive!

2.The advantage of cold forging heat sink

The cold forged heat sink is widely used in the heat dissipation of LED lamps and has the following advantages:

(1) The price of cold forging die is not high, which can effectively control the cost;

(2) High production capacity, suitable for mass production;

(3) The mold production cycle is relatively short, usually 10 to 15 days;

(4) One-time molding, the heat dissipation performance of cold forging heatsink is consistent with the heat dissipation performance of the material, and the post-processing procedures are few and simple.

(5)The major advantages of cold forging are close dimensional tolerances, good surface finish quality, and the use of lower cost materials to obtain the required strength by work hardening without requiring heat treatment.

3.Cold forging is a manufacturing process that is performed at room temperature and is suited to softer metals such as the aluminum and copper that Fodor uses for its heatsinks and precision metal products. The main advantages of the cold forging process are:

products can be produced to tight tolerances

an aesthetic surface finish removing the need for secondary finishing operations

An operator will put a piece of aluminum bar stock into the die of a cold forging press. When the press is activated, the bar stock will be 'squeezed' into the die set; taking on the shape of the die set.

Although the material started the process at room temperature, the temperature will rise to above 200°C degrees due to the friction strain rate of the blank material's deformation.

Fodor cold forges their heatsinks out of a single piece of bar-stock to achieve maximum thermal conductivity at a low price point.

4.Why is cold forging better than hot forging?

The cold forging manufacturing process increases the strength of a metal through strain hardening at a room temperature. On the contrary the hot forging manufacturing process keeps materials from strain hardening at high temperature, which results in optimum yield strength, low hardness and high ductility.

5.What metal is best for cold forging?

The most common metals in cold forging applications are usually standard or carbon alloy steels. Cold forging is typically a closed-die process. Cold forging is generally preferred when the metal is already a soft metal, like aluminum.

6.What material is best for cold forging?

Aluminium and its alloys can be successfully cold forged and extruded into soft drinks containers and tubes for ointments. By far the biggest volume material is low carbon mild steel (<0.2 wt% C) which is used to produce a wide range of components, mainly in the automotive and bicycle component industries

7.What temperature is cold forging?

250o to 450o

The Cold Forging Process

Prior to forging, the workpiece is treated with a lubricant to prevent it from sticking to the die and to keep it cool during the forming process since deforming can produce temperatures of 250o to 450o.

Note

Cold forged heat sink

An added benefit of this process is that a forged heatsink of the same design can be manufactured with different heights using only one set of forging die. When working with high aspect ratio, or dense fins a forged heatsink has no thermal interface between the fins/pins, and the base which will provide better performance compared with stamped-fin or bonded-fin heat sinks. Heat distribution can be further improved in aluminum heatsinks by embedding a copper inserts into the base during the forging. As this process is fairly expensive, for small volumes it may be worth exploring extrusion with a cross cut to produce square pins. For larger volumes die cast is a good alternative.

Fodor has gained experiences in the manufacturing techniques for high power cold forged heat sink. We have resolved the problems such as the low thermal conductivity of die-casting micro-channels and higher costs for machining micro-channels. We have already applied cold forging heatsink to cooling solutions including high-voltage inverters, wind power converters, and electric motor controllers.

1. Manufactoring process: Cold forging process

2. Material: AL1070

3. Surface treatment: Clear/black/red/gold anodizing

4. Product type: Customized Design

5. Packing: export standard carton box with pallet.

6. Application: Industry/medical/measurement/house

you have any inquiry, please contact us.

Fodor is the leading heat sink manufacturer in China, provides heat sinks and cold plates and offer customized cold forging heat sink and the other heat sink, for example, aluminum profile heat sink,skived heat sink,die casting heat sink,cold plate, if you need any heat sink, please contact fodor .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!