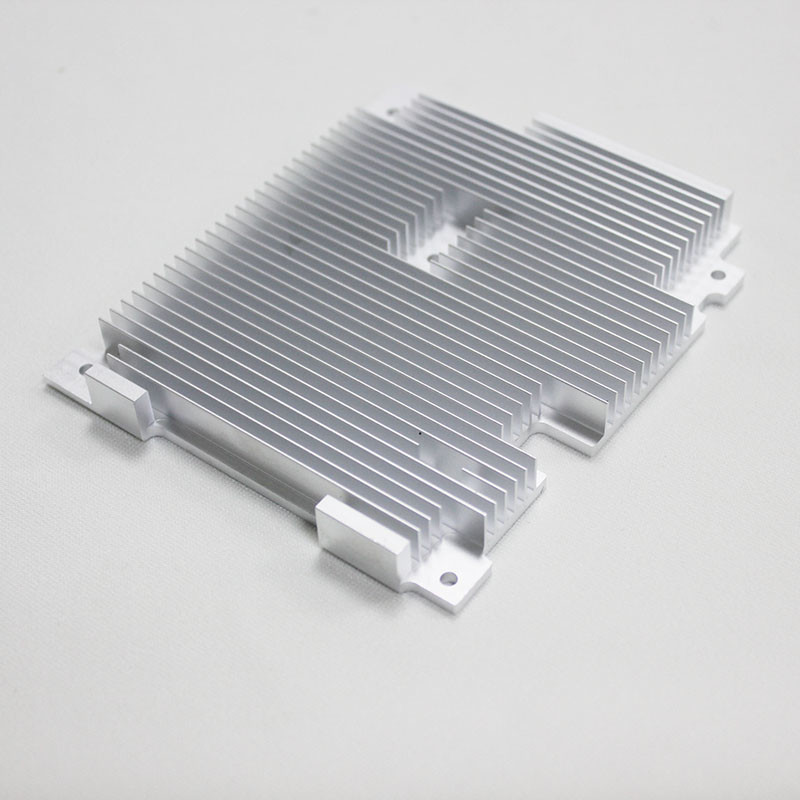

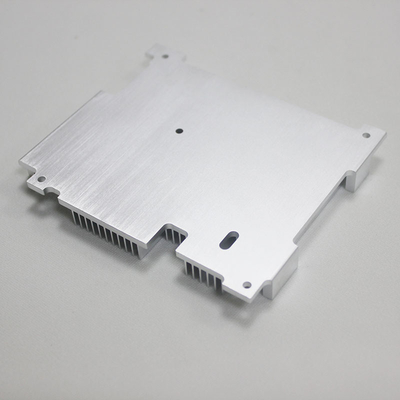

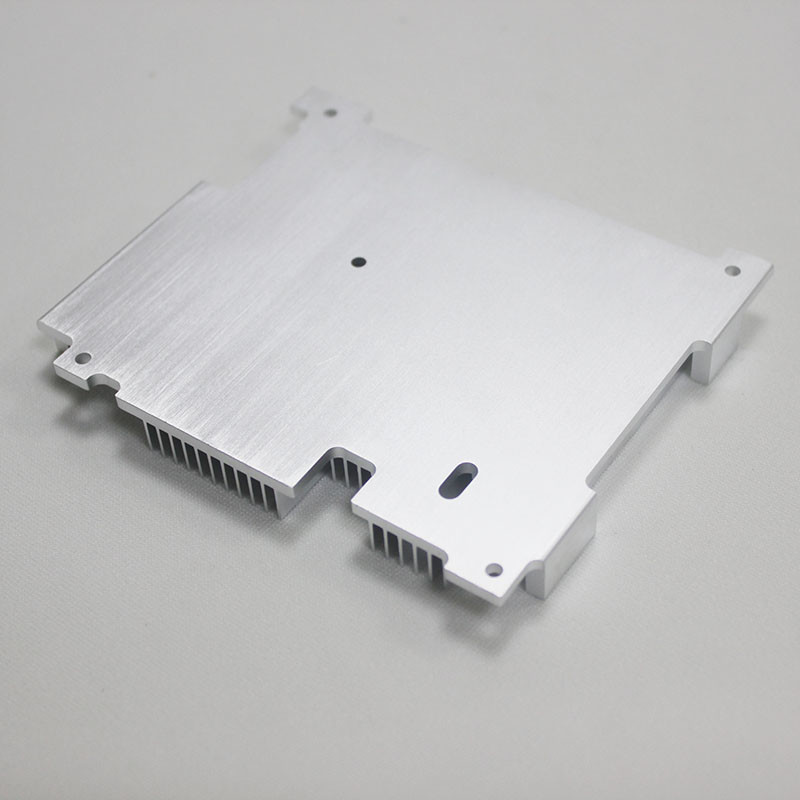

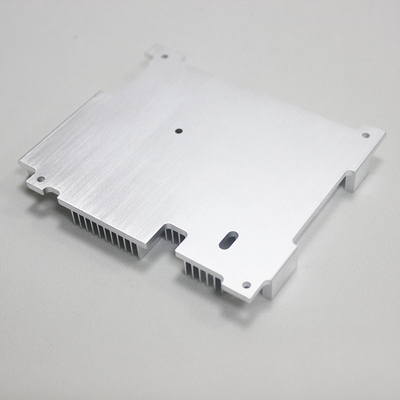

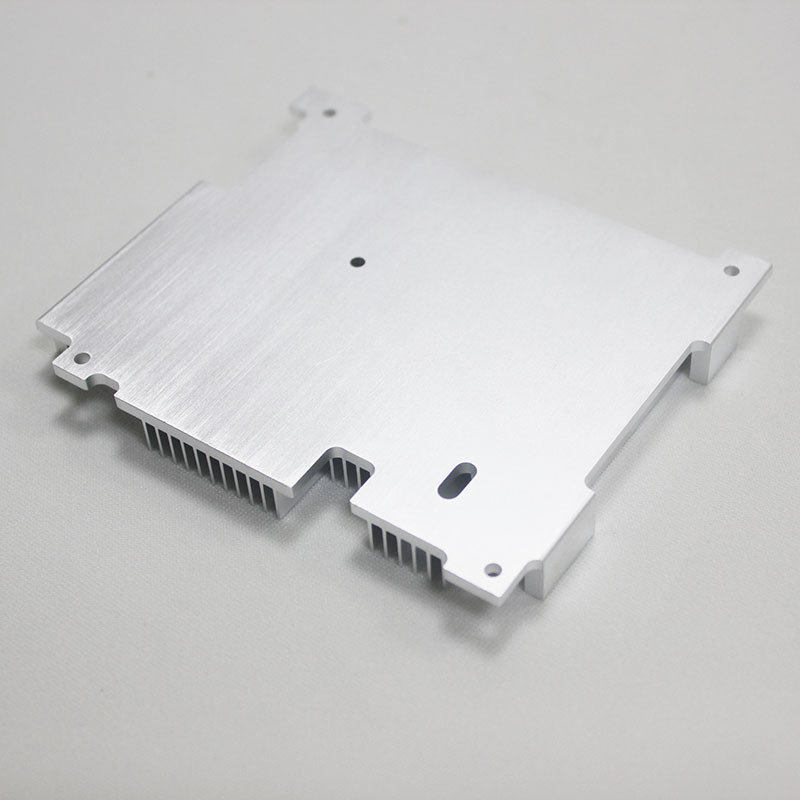

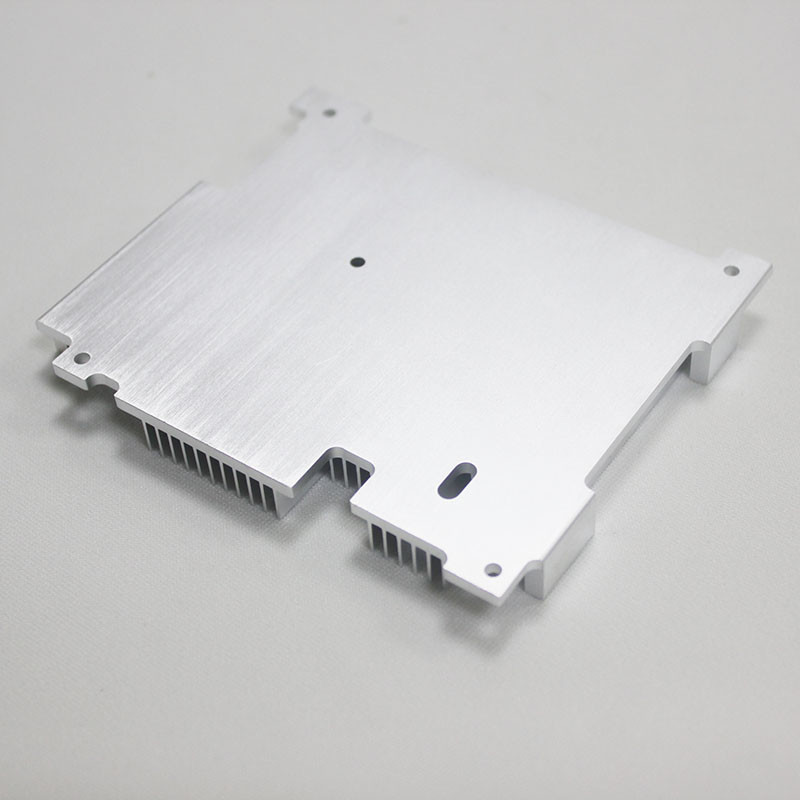

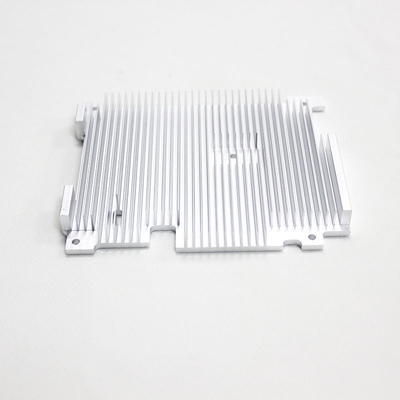

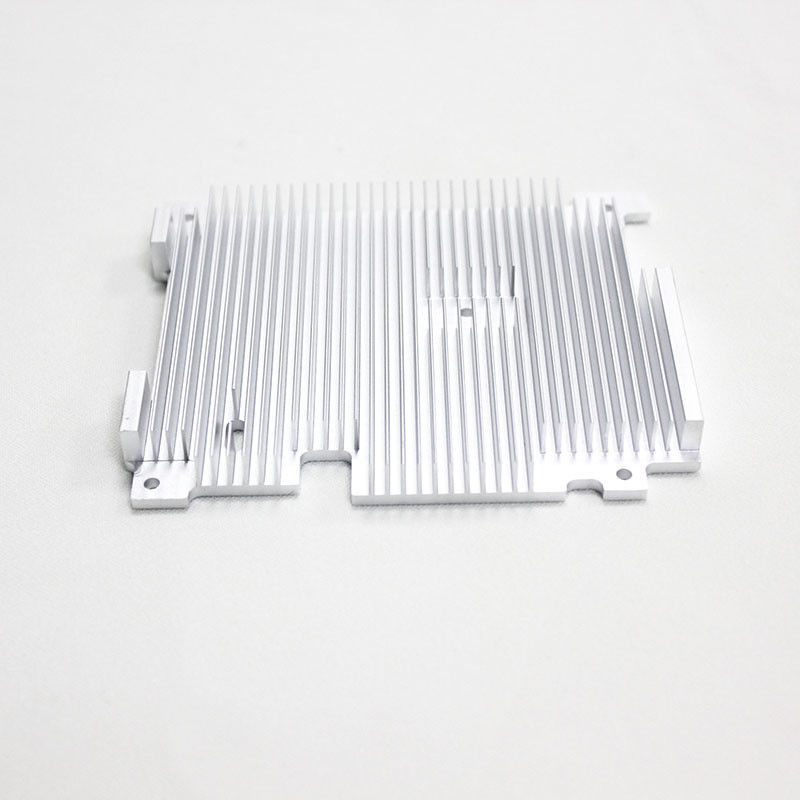

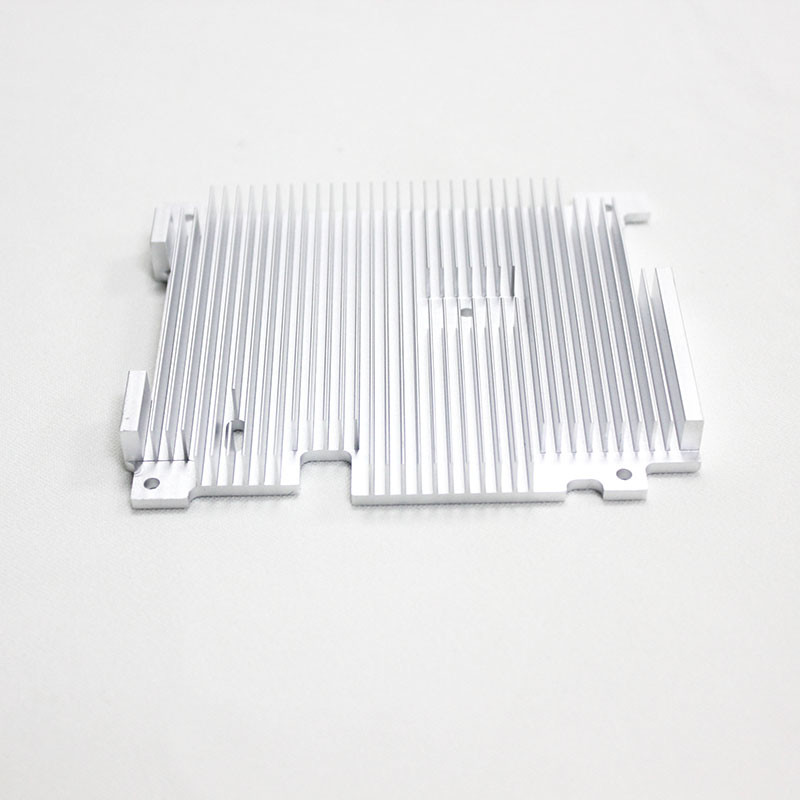

Aluminium Profile Custom Heat Sink For European Telecommunication Router

Quick Detail

| Raw Material |

AL6063-T5 |

| Custom Service |

Yes, OEM/ODM Service |

| Free design service |

We can offer the free design heat simk service. |

| Processing Technology |

Cutting/Wood machining/CNC/Riveting |

| Surface treatment |

Anodizning Black |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

LED housing heat sink |

| The other styles heat sink |

We can offer cold forging heat sink, skived heat sink, die casting heat sink, heat pipe heat sink, cold plate

|

Description

This aluminum profile housing heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

CATEGORY: HEATSINK ENCLOSURES・HEATSINK CASES・COOLING CASE・HEAT DISSIPATING ENCLOSURE・FANLESS ENCLOSURE

RFQ

What is the most effective heat sink?

Copper is one of the best materials to choose for heat sinks as it has a high thermal conductivity. But aluminum is most commonly used due to it's lower cost and relatively high thermal conductivity.

A custom heatsink is a good choice for the for the most challenging applications. In the simplest form, Fodor can use one of our wide range of standard heatsinks, and then modify to meet the thermal application requirements. Customizing a standard heatsink helps reduce a heatsink cost, and also can reduce the prototype time dramatically. For larger heatsinks, we can also look an existing extrusion before it has been cut for a standard heatsink. Where a standard heatsink can not be modified, our engineering team will then design a custom heatsink solution using the most appropriate manufacturing process.

Metals with excellent thermal conductivity such as diamond, copper and aluminum make the most efficient heat sinks. However aluminum is more commonly used due to its lower costs.

Other factors that affect a heat sink’s performance include:

- Thermal Resistance

- Airflow

- Volumetric resistance

- Fin density

- Fin spacing

- Width

- Length

Heat sinks are used to cool various electronics components whose heat dissipation abilities are is insufficient to dissipate all the excess heat. These devices include:

- Power transistors, thyristors and other switching devices

- Diodes

- Integrated circuits

- CPU Processors

- Graphic processors

- LEDs

The heat sinks can further be classified by their physical designs and shapes, material used and more. Typical heat sinks are:

- Stamped

- Machining

- Bonded-fin

- Folded-fin

- Forged Heat Sinks

- Single Fin Assembly Heat Sinks

- Swaged Heat Sinks

- Skived Heat Sinks

Notes

What is aluminum profile used for?

Aluminium profiles are by-products usually for structural purposes. It is possible to distinguish three types of profiles according to their use: construction, architectural and industrial. Construction profiles: this profiles offers high bending and torsional stiffness despite their low net weight

Why do you need a heatsink?

What is the purpose of a heat sink? A CPU is prone to overheating because some of its components product heat. Without the heat sink, the heat generated by the components stay in your CPU, which will burn or fry it. Because most components are made of electronic chips, they absorb heat easily

We offer the Aluminum Profile Heat sink service for custom and exsiting mold for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!