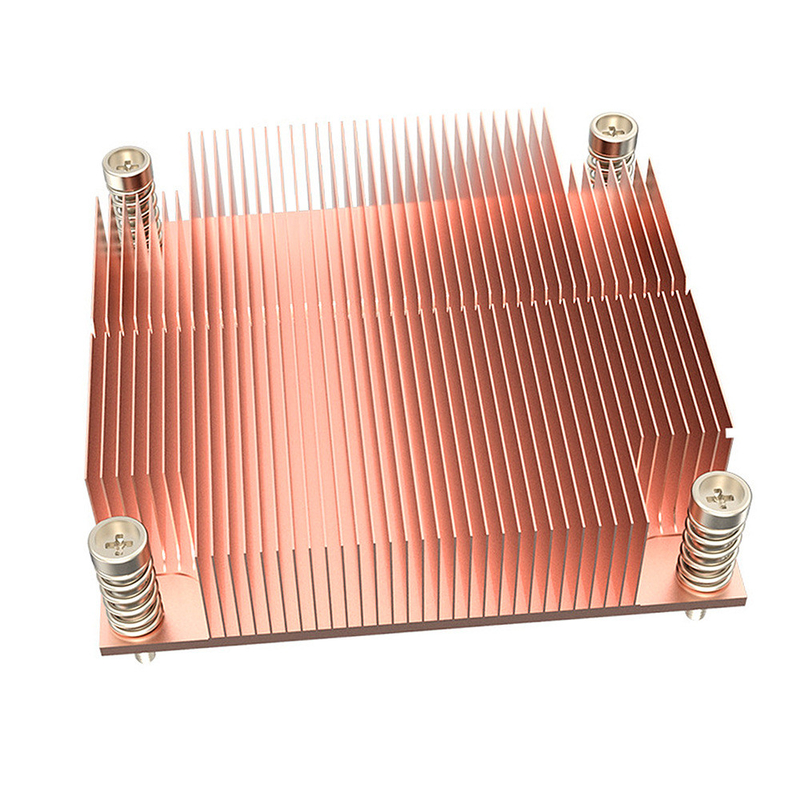

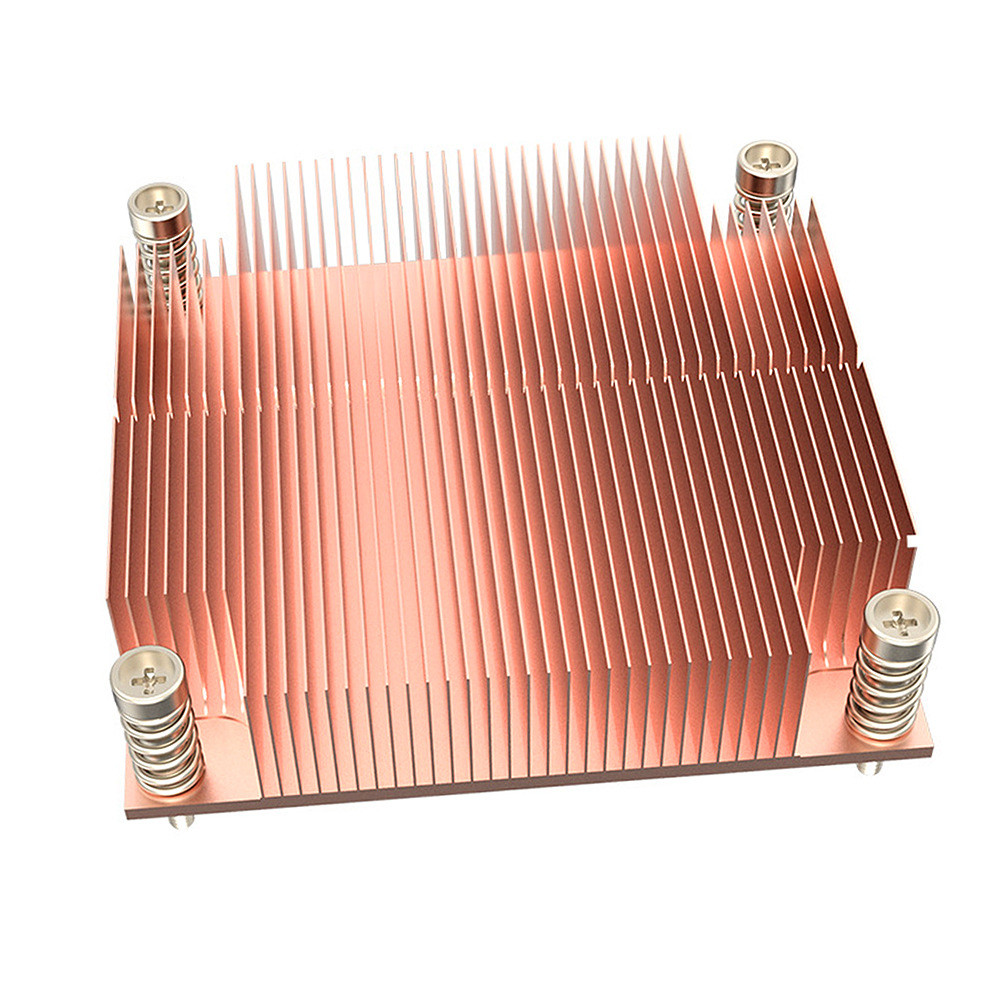

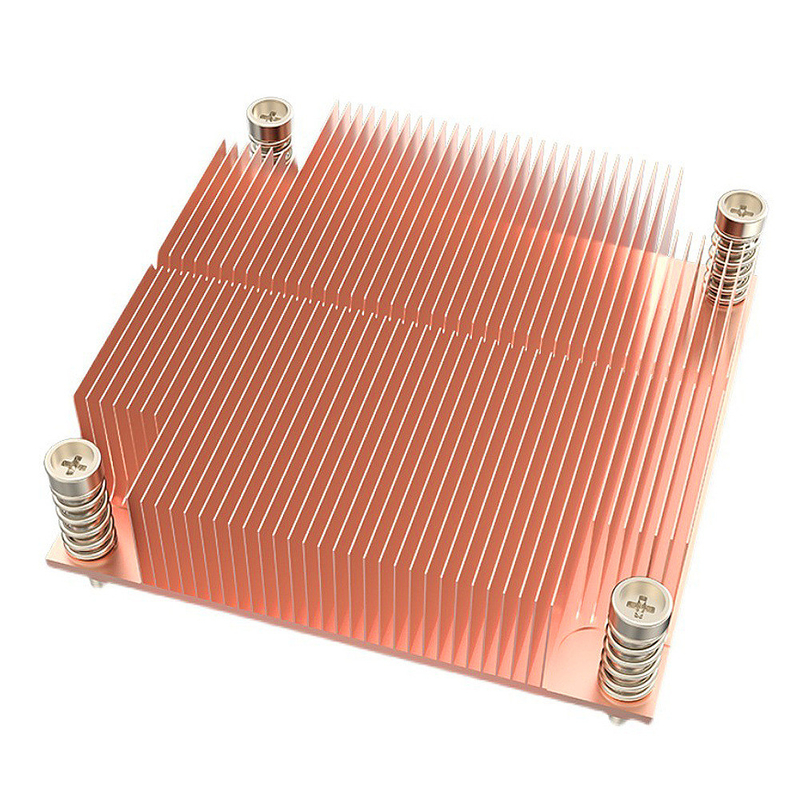

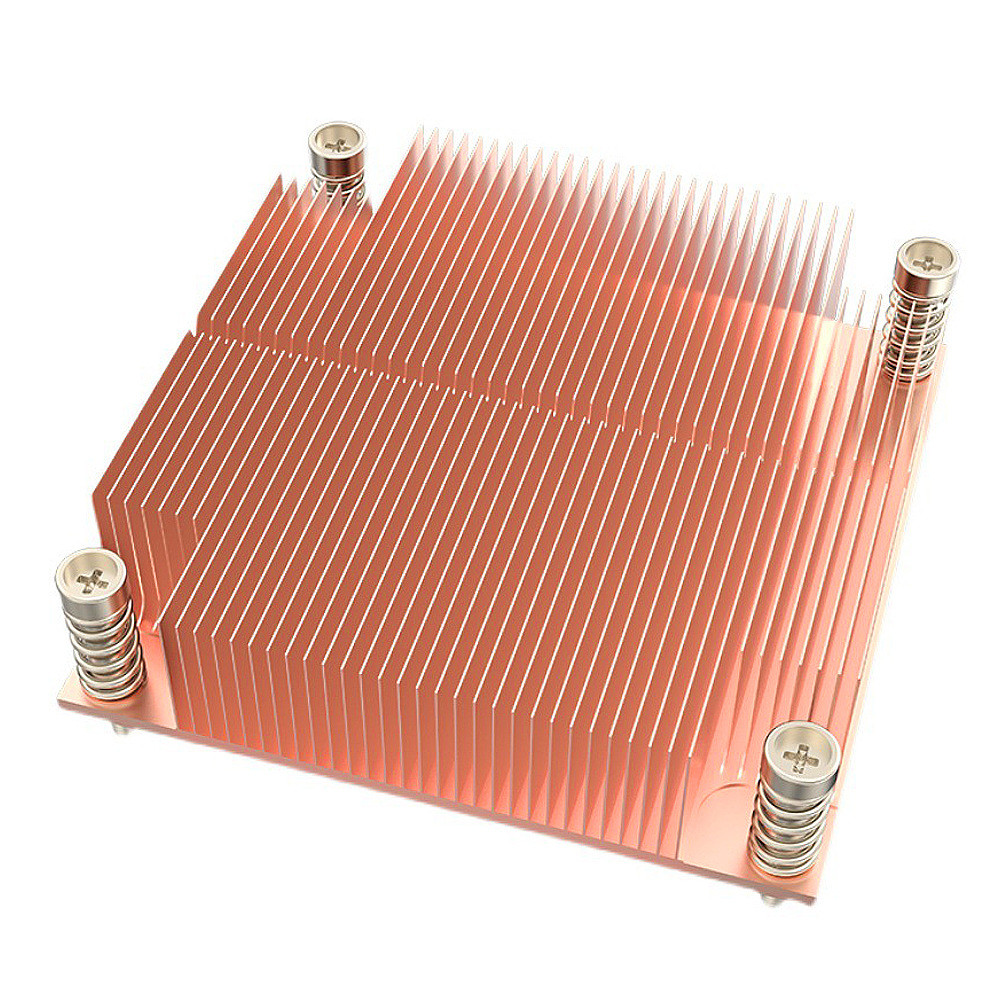

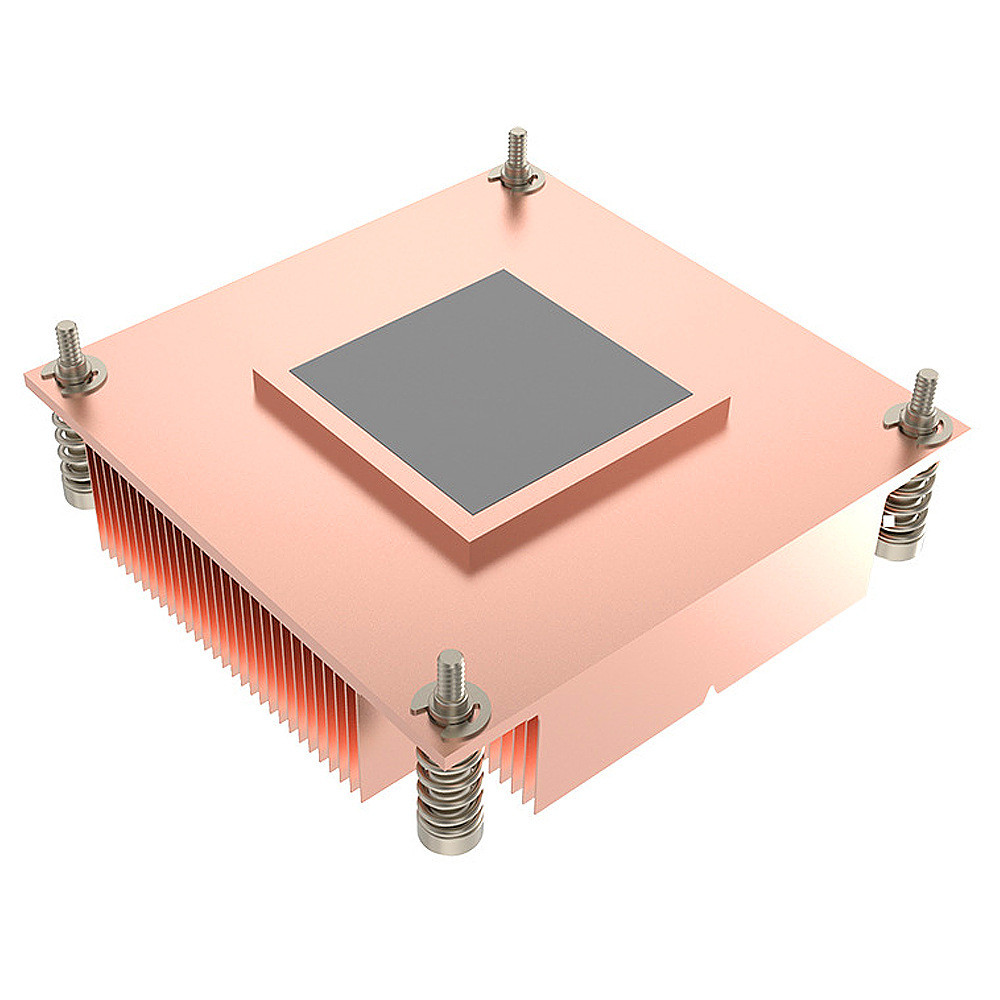

88X88XX25mm Passivation/650 Copper C1100 Intel 1700 Skived 120W Heat Sink

Description Of Aluminum Heat Sink

Skived Fin Heat Sinks offer highly optimized cooling as they allow for higher fin densities than what is manufacturable using extrusion methodologies, but do not have an interface joint that restricts heat flow like bonded or brazed fin heat sinks. Unlike bonded or brazed heat sinks, Skived Fin Heat Sinks are constructed from a single piece of material and offer reduced thermal resistance since there is no joint between a base and fins. These heat sinks are manufactured by precisely slicing the top of the base, called skiving, folding it back to where it is perpendicular to the base, and repeating at regular intervals to create fins.

The skiving process enables high fin density and thin fin heat sink geometries for optimal thermal performance. By packing as much fin surface area into a given volume, skived fin heat sinks have greater heat transfer than other single piece construction heat sinks such as extruded aluminum heat sinks. Compared to extruded aluminum, skived fin heat sink fabrication does not rely on expensive tooling, providing greater design flexibility and faster prototyping. Instead, each fin is cut separately using the same tool which allows for lower tooling costs. This enables Fodor Technology to fully customize skived fin components for your product, which also includes liquid cooling applications.

Skived heat sinks can be constructed of aluminum or copper allowing for full, one-piece copper solutions for high performance cooling. Fodor's standard copper skived fin heat sinks are available with Shurlock pin attachments for reliable mounting and easy assembly.

The 1u copper heatsink with high precision tight joint, fine workmanship, so that the distance of each skiving fin is consistent, the air flow evenly and smoothly through each piece of skiving fin, enhance the thermal performance, with one-time molding, No loss of heat dissipation performance, good heat dissipation effect.

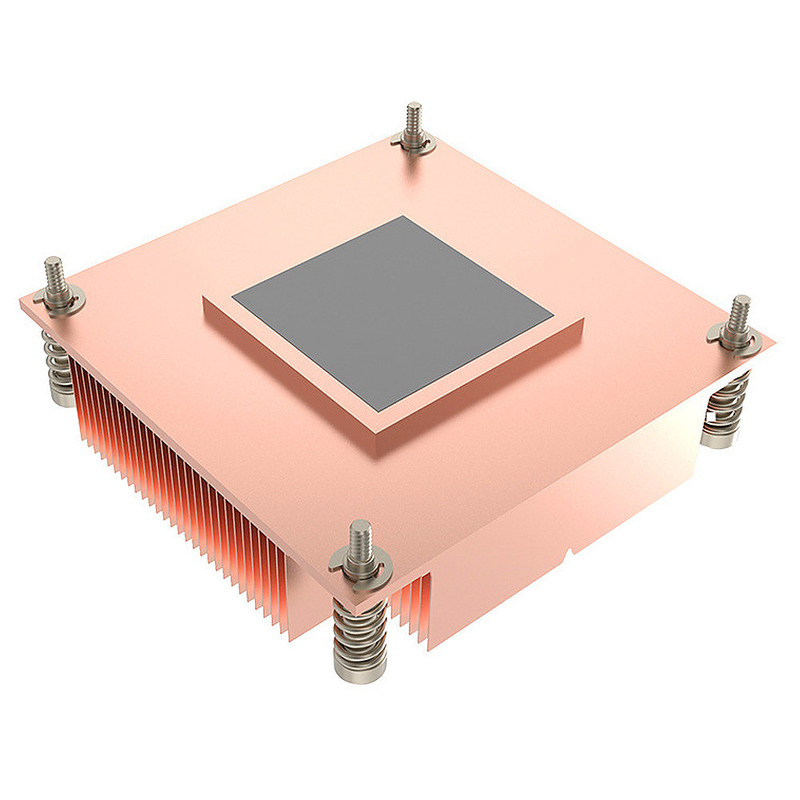

The copper cpu heatsink's height is only 23mm structure design, good cooling performance, suitable for compact space and small size CPU heat dissipation.

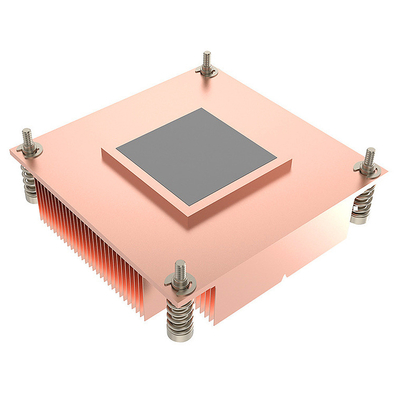

The 7762 thermal grease imported of the Lga 1155 passive heatsink from Japan is high performance silicon. Nickel plating Nickel plating process for increased beauty and oxidation resistance

Zero distance contact of copper base is conducive to the heat generated by CPU to conduct around in the first time, attach to CPU heating core, absorb and conduct every minute of heat in time.

Specification Of Skived Heat Sink

| Raw Material |

Copper |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment |

Deactivation |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Electronic equipment heat sink |

| MOQ Request |

100/500/1000 |

Feature Of Aluminum Heat Sink

High aspect ratio, straight fin heat sinks that are ideal for compact PCB environments

Fabricated from extruded aluminum, which minimizes thermal resistance from the base to the fins, reduces weight and keeps costs low

Higher performance helps ensure reliable product life at a lower cost than other extruded heat sinks

Comes standard without interface material or with most common pressure sensitive thermal tapes as a custom option

Application Of Aluminum Heat Sink

Aluminum heatsink is light in texture, but its strength is relatively high. It is close to or exceeds high-quality steel. It has excellent thermal conductivity and corrosion resistance, good heat dissipation performance, and good energy-saving effect.

After the aluminum heatsink has been surface-oxidized, an oxide film is formed on the surface of the heatsink. This film is tough and dense, preventing further corrosion of the bulk material, increasing the corrosion resistance, wear resistance and appearance of the aluminum material. Aesthetics.

The application areas of aluminum heatsinks are

Power, electronics, communications, machinery, automobiles, solar photovoltaic power generation, wind power, construction machinery, air compressors, railway locomotives, household appliances and other industries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!