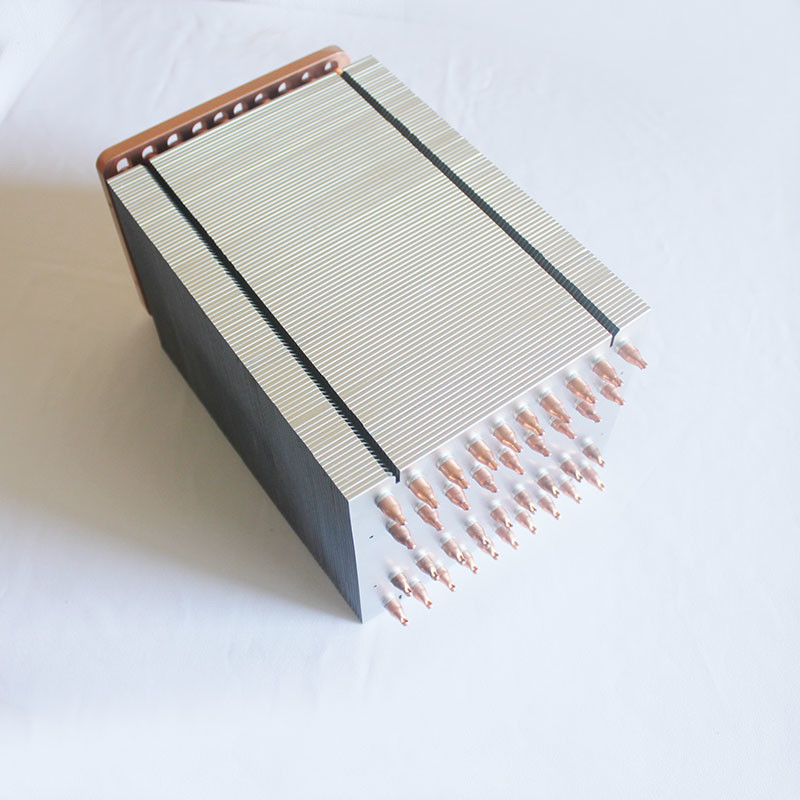

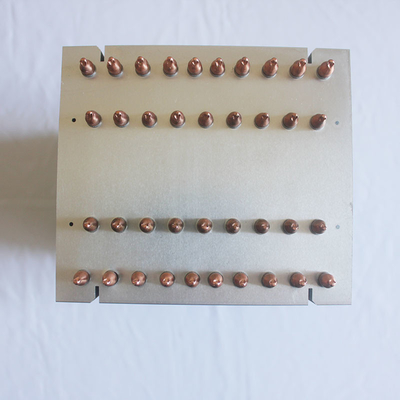

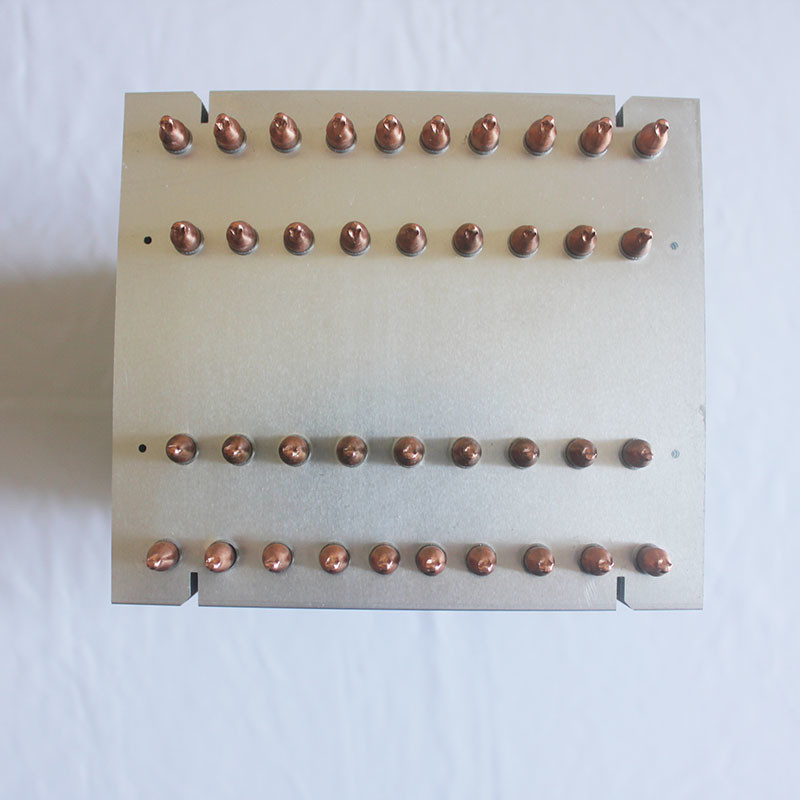

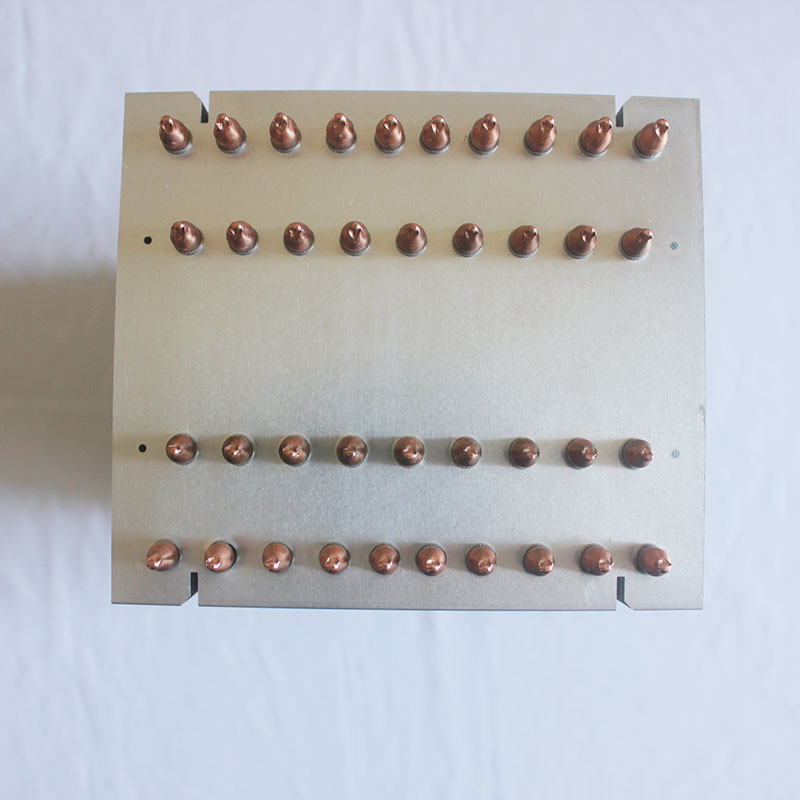

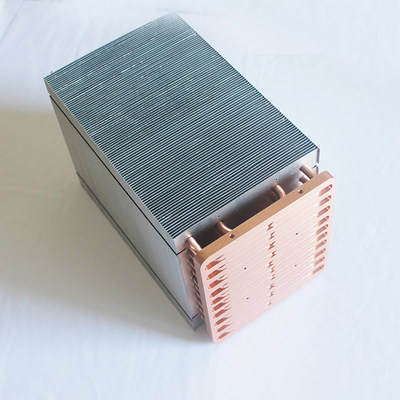

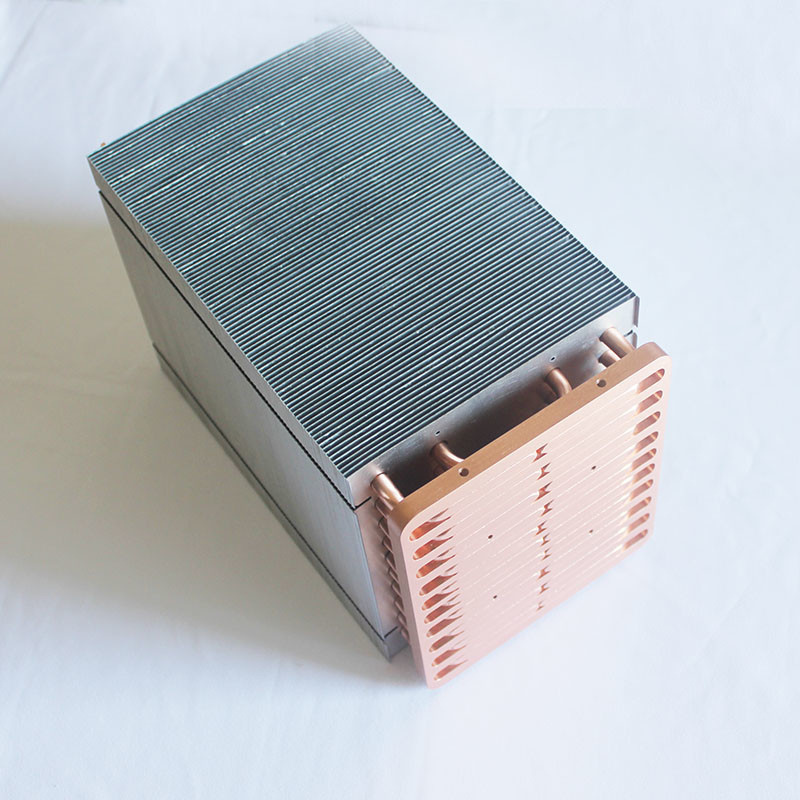

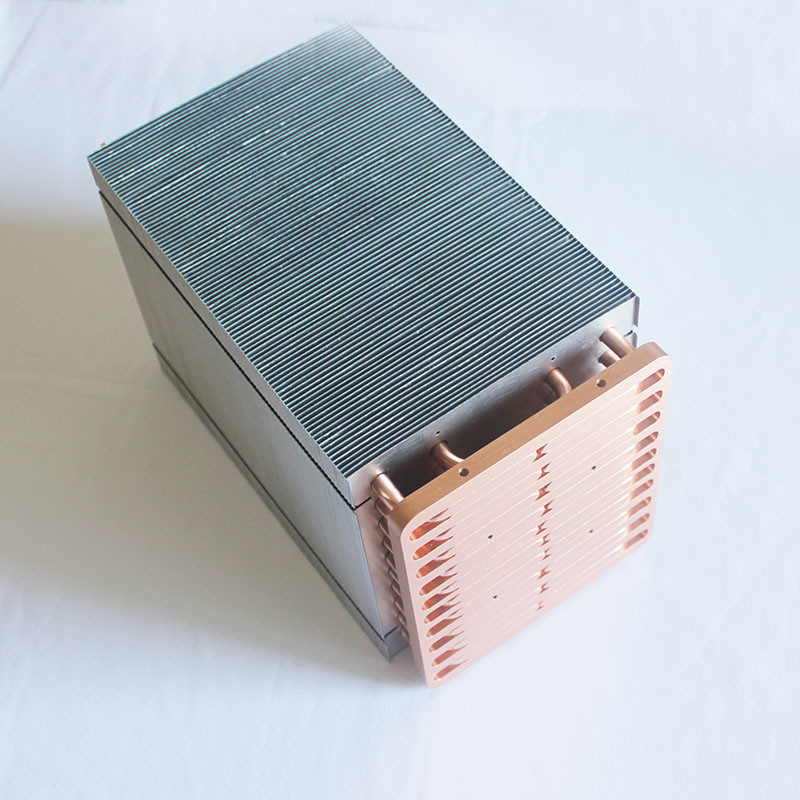

Free Design Factory 2000W Heat Pipe Heat Sink For LED Big Power Lighting

Quick Detail

| Raw Material |

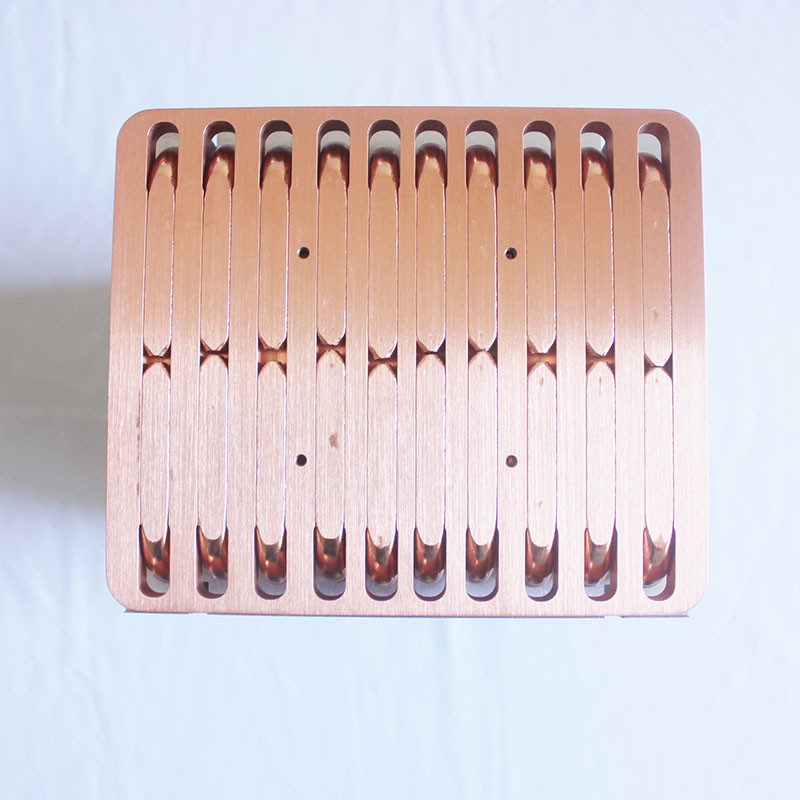

AL1050 and 38 heat pipe / cooper |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

Cutting/Wood machining/CNC/Riveting |

| Surface treatment |

plating nickel |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Electronic equipment heat sink |

| MOQ Request |

100/500/1000 |

Description

Heat pipe radiator is a new product produced by using heat pipe technology to make major improvements to many old radiators or heat exchange products and systems. There are two types of heat pipe radiators: natural cooling and forced air cooling. The thermal resistance of air-cooled heat pipe radiator can be made smaller, and it is often used in high-power power supplies.

Note

Side-blown radiator

Side-blowing radiators are extremely common on public graphics cards. We often see "brick" integrated radiators such as the public ATI Radeon HD 5870 and the public GeForce GTX 470 as the most typical side-blown radiators. The side-blowing radiator uses the side air flow generated by the rotation of the turbo fan to suck air from the inside of the chassis, and then pass through the air guide grooves, fins, heat pipes, etc., and discharge the heat to the outside of the chassis through the air outlet at the rear of the graphics card.

The disadvantages of side-blown radiators are mainly insufficient heat dissipation and unsatisfactory noise control.

Since the side-blowing radiator requires a long air guide channel and the fins are arranged inside the channel, a turbo fan is required to ensure a certain amount of air flow to allow air to flow out of the channel at a fast enough speed and take away heat. However, due to its size, the air volume of a turbofan is often unsatisfactory at low speeds. Once it is operated at a high speed, the noise of the cutting airflow of the turbofan blades will rise sharply. In actual use, some public graphics cards with turbo radiators have a core temperature of about 60°C in standby mode, while the core temperature quickly soars to 80-90°C under full load, and the noise will increase accordingly.

Although the side-blowing radiator has obvious disadvantages, in order to ensure that the temperature of the entire system in the chassis will not rise rapidly due to the heat of the graphics card, the mid-to-high-end graphics card in the public version uses an external side-blowing radiator. Only some graphics cards with lower heat output will choose other cooling modes.

Advantages: heat is discharged outside, does not aggravate the heat accumulation inside the case, and the temperature control effect inside the case is excellent (only refers to the outside heat dissipation). Disadvantages: The turbo radiator is noisy and the temperature control effect is not good enough.

The heat pipe radiator has the following advantages:

- The thermal response speed is fast, and its ability to transfer heat is more than 1000 times larger than that of copper pipes of the same size and weight;

- Small size and light weight;

- High heat dissipation efficiency, which can simplify the heat dissipation design of electronic equipment, such as changing air-cooling to self-cooling;

- No external power supply is required, and no special maintenance is required during work;

- It has good isothermal properties. After heat balance, the temperature gradient between the evaporation section and the cooling section is quite small, which can be approximately regarded as 0;

- The operation is safe and reliable, and does not pollute the environment.

We can offer the heat pipe radiator service, small qty is acceptable.

Technical Support

We can offer the design and simulation service. For example, our German customer's case.

According to the simulation results,the simulated chip is in compliance with the temperature requirements specficied by customer.

FAQ:

1.What is the difference between a heat sink and a heat pipe?

Smaller heat sink reduces the weight of the luminaire dramatically. This reduces transportation costs as well as the amount of other materials needed. The Heat Pipe effectively transfers heat from the heat source and as a result makes the cooling faster than ever

2.

Why do laptops use heat pipes instead of heat sink?

Heat pipes are very common in laptop computers, where there is not room to install a CPU fan. The heat pipe carries the heat away from the CPU, to the computer's fan, which then helps dissipate the heat.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!