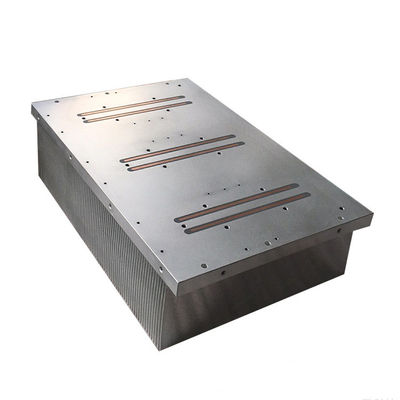

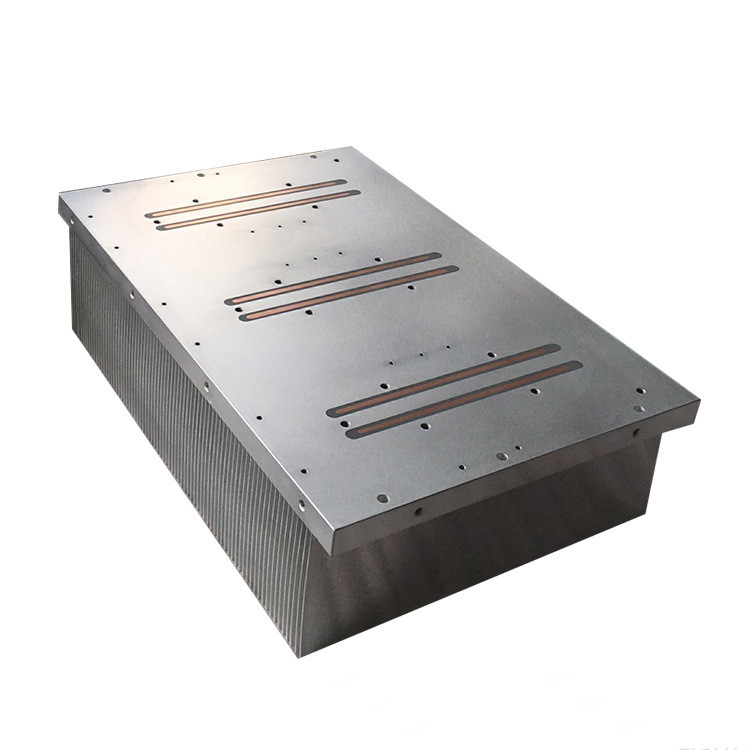

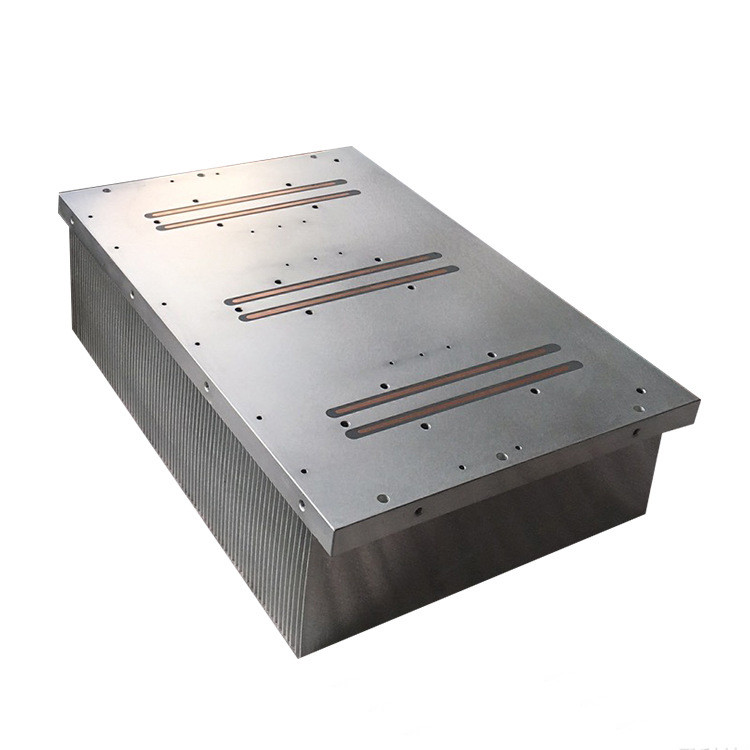

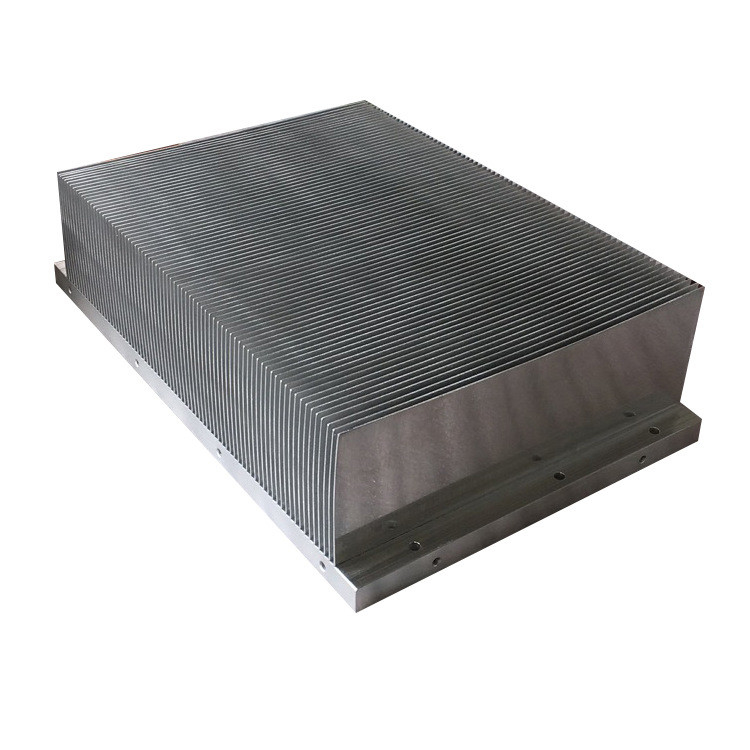

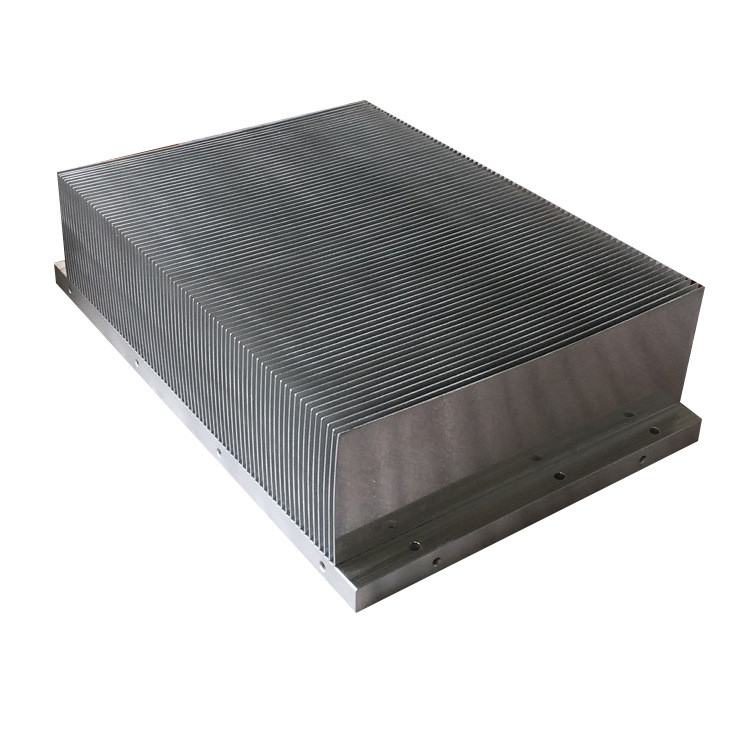

Customized Service Quality Description Of Aluminum1060 Skived Fin Heat Sink With Heat Pipe

Description Of Copper Skived Fin Heat Sink

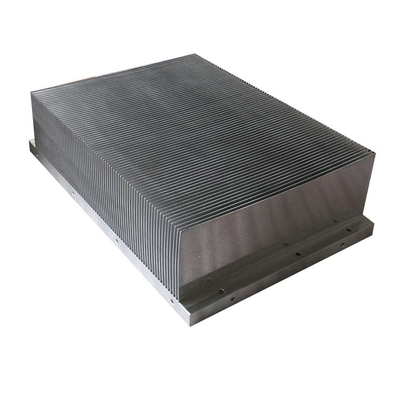

Skived aluminum heat sinks offer the maximum heat dissipation in applications that have high airflow and small space. The thermal conductivity of aluminum (~226 W/m-K) is the highest among all the commercial metals, and the skiving technology allows the heat sinks to have very thin fins, high aspect ratio and high fin density. Because the fins are an integral part of the base, skived aluminum heat sinks provide the best possible thermal conductivity between the fins and the base. When optimized to specific applications, skived Aluminum heat sinks offer outstanding performance over any other thermal solutions within the small space. In some applications, the skiving technology is also the most cost-effective and reliable method of producing heat sinks that meet high thermal demands.

Specification Of Skived Heat Sink

| Raw Material |

Aluminum |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment |

Deactivation |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Electronic equipment heat sink |

| MOQ Request |

100/500/1000 |

Design Guidelines

- Material: Copper (C11000) or Aluminum (6063/1060)

- Maximum width: unlimited

- Maximum fin length: 500 mm (20″)

- Maximum fin height: 100 mm (4”)

- Recommended fin height: <50 mm (2”)

- Recommended thickness for aluminum fins: 0.2-1.2 mm (0.008-0.047”)

- Recommended thickness for copper fins: 0.1-0.6 mm (0.004-0.024”)

- Minimum fin spacing (gap): 0.1 mm (0.004”)

- Maximum fin spacing (gap): 8.0 mm (0.31”)

How is a Skived Heatsink manufactured?

A Skived Heatsink is manufactured using a skiving machine that uses a blade to cut material in thin slices, and then push the skived fin up. For a heatsink application, the manufacture of ultra thin fins is possible, and we have produced fins as thin as .008”. The process allows high aspect ratios that provide greater surface area for maximum heat dissipation. We typically use this process for copper Skived heatsinks, however Aluminum Skiving is possible. As this is very easy to set up, typically there are minimal setup fees which allow for rapid prototyping of new designs. It is possible to machine additional features after the skiving process has been completed, but requires an experience to avoid stresses on the heatsink.

Feature Of Aluminum Heat Sink

The skiving process enables high fin density and thin fin heat sink geometries for optimal thermal performance. By packing as much fin surface area into a given volume, skived fin heat sinks have greater heat transfer than other single piece construction heat sinks such as extruded aluminum heat sinks. Compared to extruded aluminum, skived fin heat sink fabrication does not rely on expensive tooling, providing greater design flexibility and faster prototyping. Instead, each fin is cut separately using the same tool which allows for lower tooling costs. This enables Fodor Technology to fully customize skived fin components for your product, which also includes liquid cooling applications.

The Skiving Process

Skived heat sinks are manufactured by peeling fins from a bar of solid copper or aluminum, using a sharp and accurately controlled blade tool. The tool shaves a small thickness of the material, lifts it up and bends it vertically to form the fin. The final heat sink can be machined using normal fabrication techniques, such as CNC machining. Skived heat sinks require minimal tooling cost, which makes it a cost effective solution. Skived heat sinks can also be customized with embedded heat pipes to further improve performance.

Application Of Aluminum Heat Sink

Skived copper heat sinks deliver maximum heat dissipation in applications with limited space and high levels of ventilation. They are a cost effective solution when considering the low tooling cost and the optimized fin surface area.

Skived fin heat sinks are commonly found in the following applications:

- Computers and electronic components

- Telecommunication equipment

- Industrial equipment and components

- Lighting lamps and household appliances industry

- Automotive components

Skived heat sinks can be constructed of aluminum or copper allowing for full, one-piece copper solutions for high performance cooling. Fodor's standard copper skived fin heat sinks are available with Shurlock pin attachments for reliable mounting and easy assembly.

For rapid thermal modeling and comparison of multiple heat sink constructions please try to contact us, we can offer the free design.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!