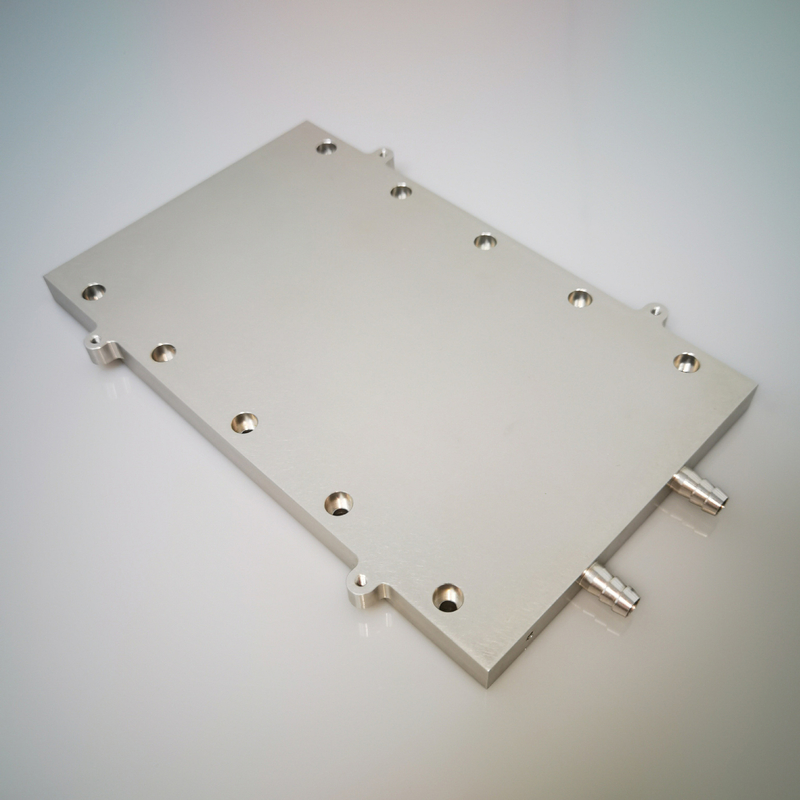

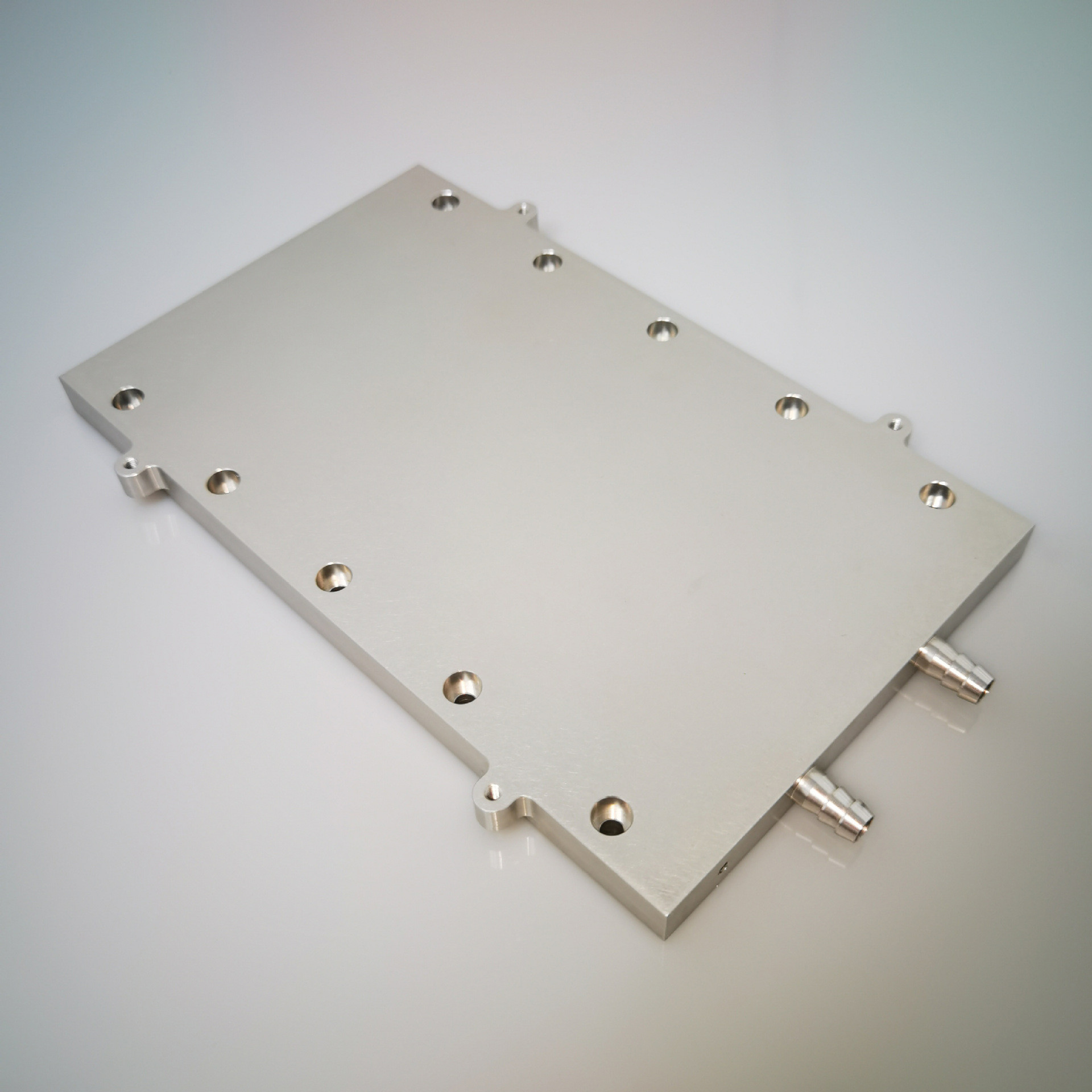

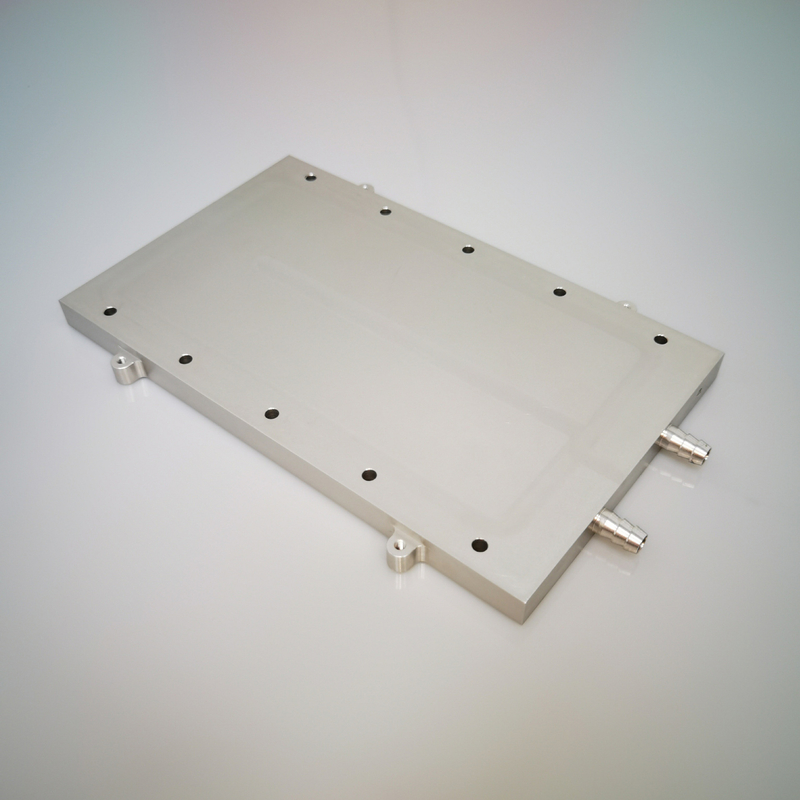

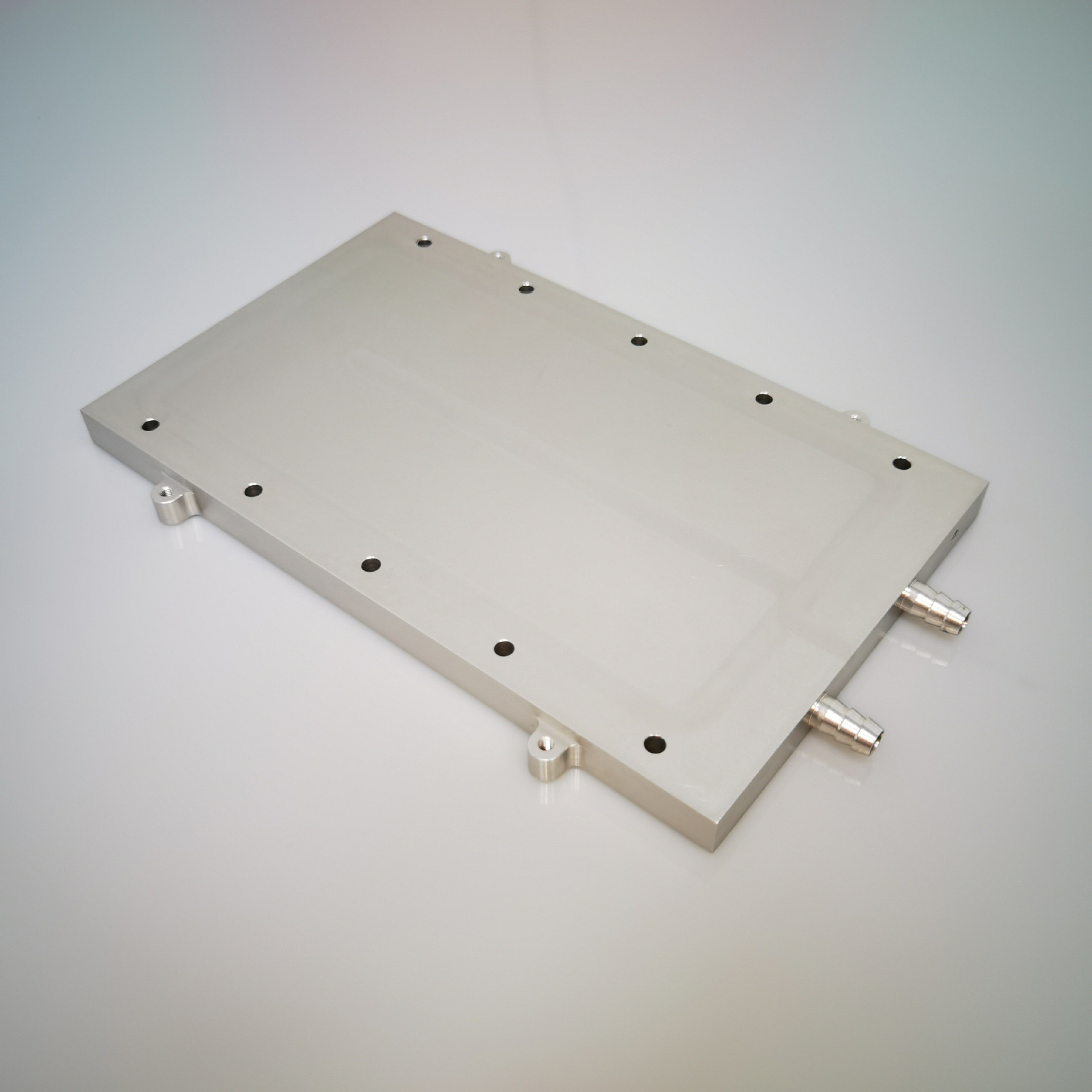

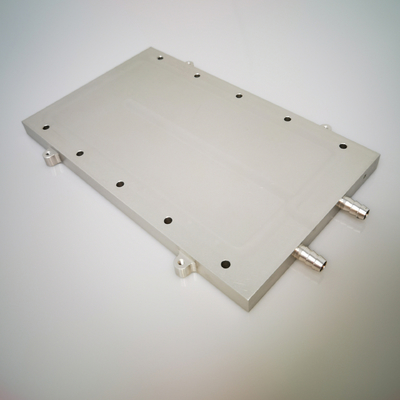

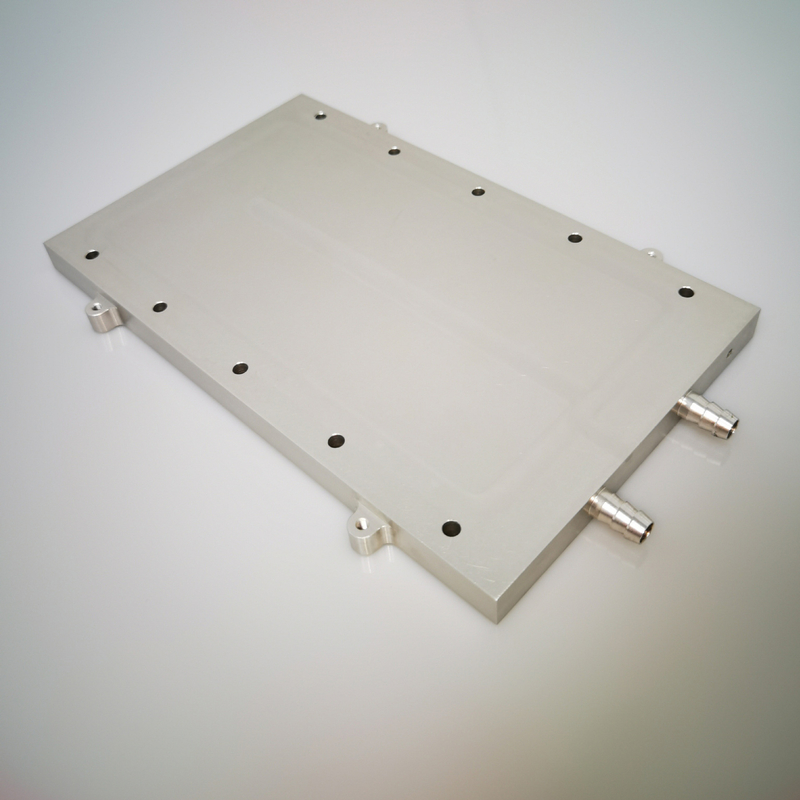

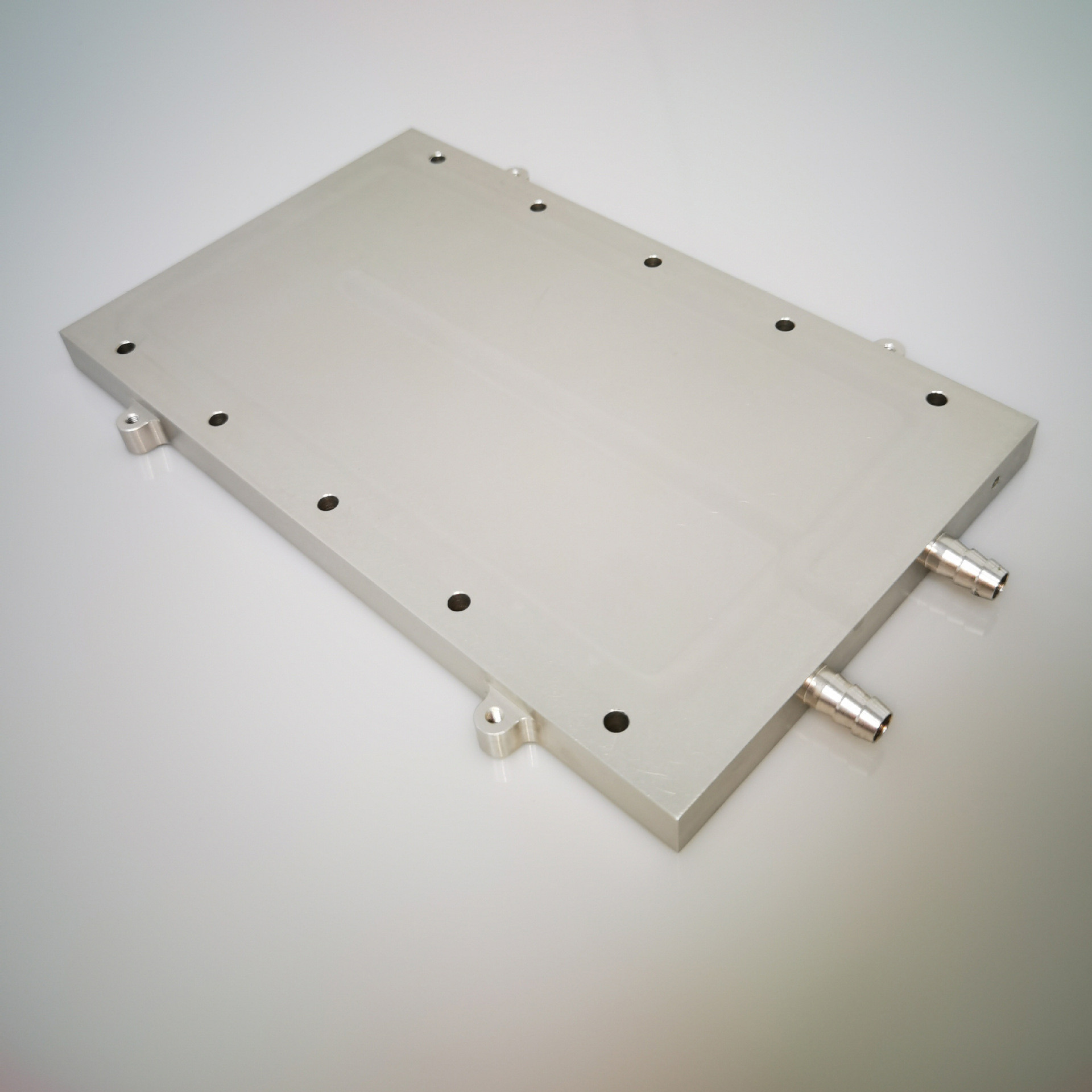

Customized Liquid Cooled Heatsink Water Cooling Plate For Industry Equipment

Quick Detail

| Raw Material |

AL1050 |

| Custom Service |

Yes, OEM/ODM Service |

| Quality System |

ISO9001:2015 |

| Processing Technology |

Cutting/Wood machining/CNC/Riveting |

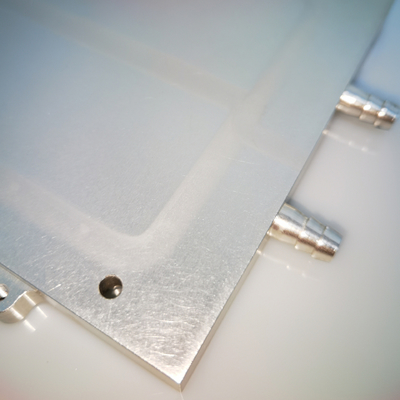

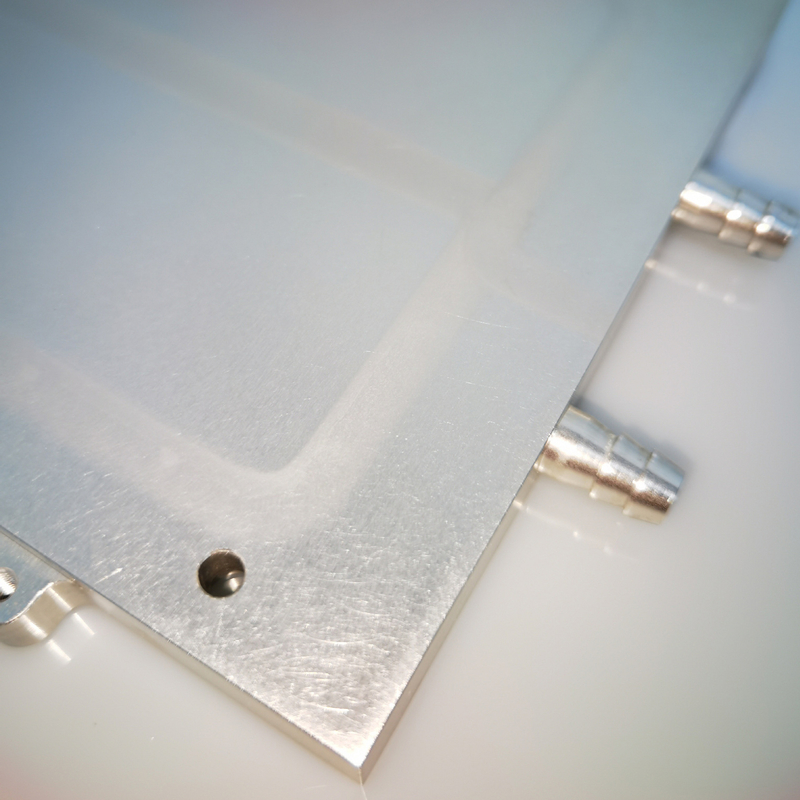

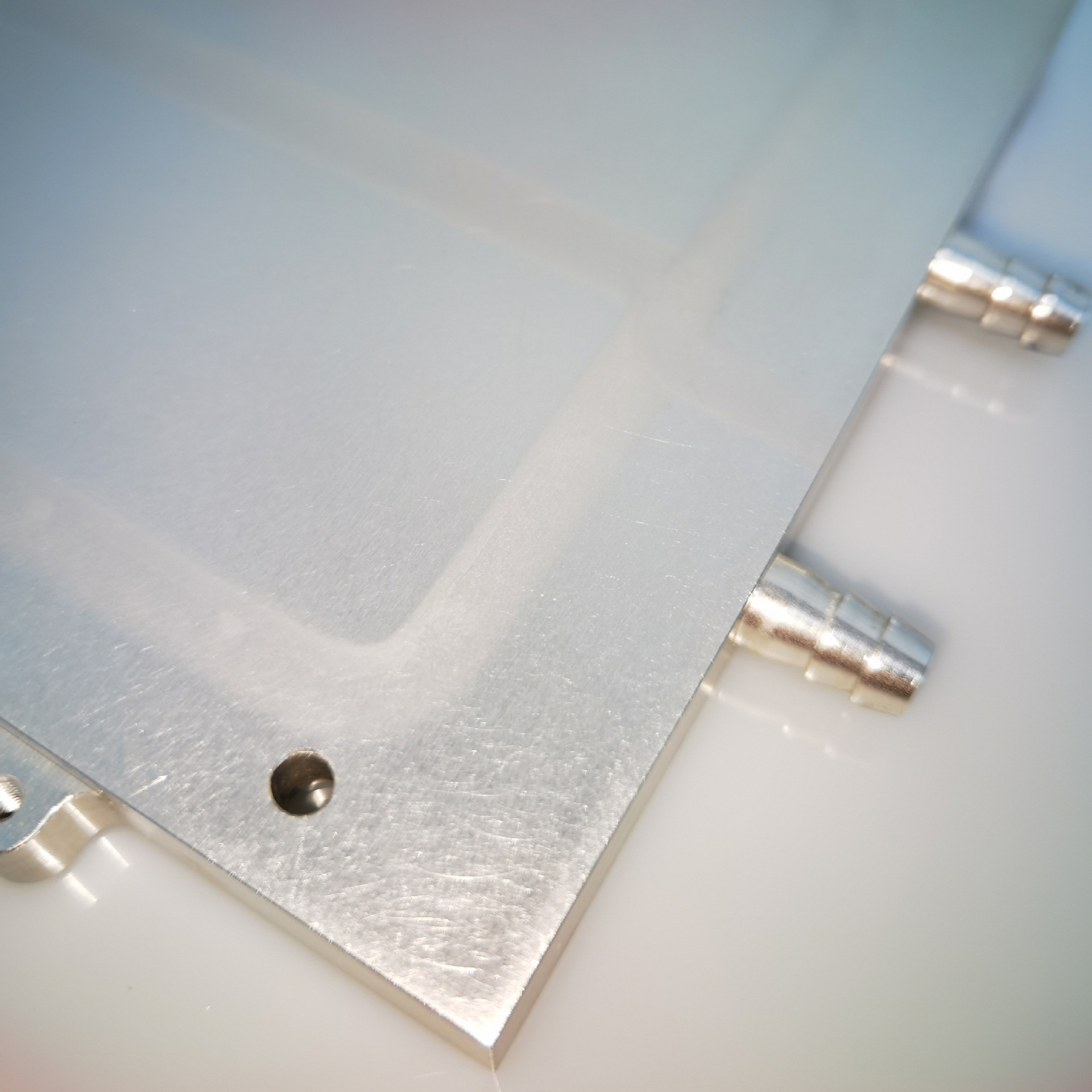

| Surface treatment |

Plating nickel |

| Packing Way |

Blister packaging or special packing you would like |

| Application Scenario |

Electronic equipment heat sink |

| MOQ Request |

100/500/1000 |

WHAT IS A LIQUID COLD PLATE?

A cold plate is responsible for taking the heat from the device(s) and transferring it to a single-phase liquid coolant, circulating through internal channels of the plate and subsequently rejecting it downstream to a radiator. There are several thermal/mechanical advantages of a cold plate solution. .

Note

Liquid heat sinks are also called water-cooled radiators and liquid-cooled radiators. They are generally made of aluminum and used to dissipate heat. They are mainly used in high-power devices, such as servers, inverters, inverters, APF, SVG, IGBTs, etc., remember to have A company called Fodor Radiator Factory specializes in aluminum radiators, water-cooling plates, etc. This will install the heating element on the water-cooling plate to dissipate heat, and the internal liquid is specially designated.

Customized Liquid Cooled Heatsinks

With tight collaboration with our customers, we can design and produce almost any kind of copper or aluminium liquid cooled heatsink (other materials on demand). Our designs take in consideration the internal situation of the power chips and an especific water circuit is designed for the optimal refrigeration of the power module. Do not hesitate to ask for your application needs.

Wide Range of Liquid Cooled Heatsinks

Copper and aluminium liquid cooled heatsinks with internal channel for semiconductor cooling through water, glycol and/or oil. Appropriate for high power converters in industrial facilities with cooling circuit systems and heat exchangers. We have a standard range and we can customise any design you require. The new RG82000 series implements new fabrication FSW technology for a very reliable and high performace coldplates. RG78000 series has been specially designed for IHM/IHV y PrimePACK™3 modules. RG77000 as a low cost solution with inserted cooling circuit. RG75000 series for press-pack devices and RG76000 for 62 mm completes the standard product range from our company.

What parameters should be provided in the thermal design of the water-cooled plate?

When designing the heat dissipation of the water-cooling plate, it is necessary to provide the model of the water-cooling plate (that is, the size of the water-cooling plate), the drilling position of the water-cooling plate, the target to be achieved (including temperature difference, water pressure difference, etc.), the parameters of the joint, the power of the heat source, and Calorific value and other data

COLD PLATE DESIGN AND ANALYSIS FOR THERMAL MANAGEMENT

When designing a cold plate there are several challenges to overcome in order to create an optimal design. In many cases, there are trade-offs between design options. ACT has significant experience in meeting thermal needs while minimizing operating and manufacturing costs. Below are several key performance features we will analyze as part of the design:

- Pressure drop

- Liquid flow path

- Flow balancing

- Material compatibility

- Fluid Stability

- Temperature Uniformity

- Maximum Temperature

- Weight / Size

LIQUID COLD PLATE FLOW OPTIONS

There are several types of cold plate systems for consideration. Fodor will analyze the design requirements and recommend the proper type of cold plate for your application. Below are several of our flow options:

Serpentine Tube

- Manifold Tube

- Mini Channel

- Micro Channel

Each type of system configuration has performance trade-offs. For instance, a microchannel design increases surface area for heat transfer, however, with certain flow rates, it could cause flow instability and large pressure drops.

LIQUID COLD PLATE MATERIAL AND FLUID OPTIONS

Envelope material and fluid compatibility are crucial considerations when designing a cold plate. The team at ACT has expertise in stable compatible solutions.

---Aluminum

---Stainless Steel

---Copper

---Polymer-Based

---Water

---Deionized Water

---Water / Ethylene Glycol mixture

---Dielectric Fluids

Once the design has been completed, it can be prototyped and manufactured in our IS0 9001:2008 and AS9100:2009 quality certified manufacturing facility. You can be confident of the very best design and manufacturing practices from Fodor.

We can offer the design and simulation service. For example, our German customer's case.

According to the simulation results,the simulated chip is in compliance with the temperature requirements specficied by customer.

Technical Support

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!